Table of Contents

A wheelbarrow is a straightforward device that has been employed for moving products from one place to another for ages. A high-quality wheelbarrow is useful because it makes it simpler to transfer heavy items, especially in places where other modes of transportation, like vehicles, are impractical. This article will delve into the various parts of the wheelbarrow its basic design, underlying principles, and crucial components.

Principal

A wheelbarrow works on the basis that it employs a lever to lessen the effort needed to lift and transport large items. A wheelbarrow’s fundamental components include handles, a tray or bucket to hold the weight and a wheel.

The wheelbarrow is hoisted by the handles after the load has been placed in the tray. Next, the load is balanced on the wheel before being propelled forward. The wheelbarrow operates according to the rule of levers.

This law states that a tiny force applied to one end of a lever can result in a huge force being delivered to the opposite end of the lever. The wheelbarrow’s handles, fulcrum, and load all refer to the weight that is being transported. The leverage the handles offer reduces the amount of force needed to lift the item.

Design

A wheelbarrow is a simple yet effective tool for transporting materials and goods. It consists of a frame, handles, a bucket or tray, a wheel, an axle, braces, and a leg. The frame is made of metal or wood and is shaped like a “U” or rectangle, with two legs at the back and one leg at the front.

The handles are comfortable and angled upward, allowing for easy lifting and pushing. The bucket or tray holds the load, and the wheel and axle are located at the front for smooth maneuvering.

Braces are metal rods that distribute the load evenly across the frame and provide additional support for the bucket or tray. The leg, located at the front, helps maintain stability and prevent tipping over. Overall, the wheelbarrow is a versatile and efficient tool for transporting materials and goods.

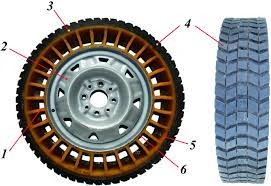

Parts of the wheelbarrow

Parts

Wheel

Trays

Handles

Front brace

Leg brace

Axel bucket

Bearing

Wheel

The component of the wheelbarrow that rolls on the ground is the wheel. It is often attached to the axle and made of metal or plastic. Depending on how the wheelbarrow will be used, the wheel size may change.

While a smaller wheel is simpler to control on flat ground, a larger wheel is better suited for irregular terrain. In order to balance the load and give it stability, the wheel is typically positioned in the middle of the tray or bucket.

For example, a wheelbarrow used for gardening may have a smaller, pneumatic wheel that can better handle uneven terrain, while a wheelbarrow used for construction may have a larger, solid wheel that can better handle heavier loads.

Pneumatic

Pneumatic tires are popular on wheelbarrows, because they offer traction and comfort, are lightweight, and are portable. However, they can have flat surfaces, especially on unpaved surfaces.

Semi-pneumatic

Semi-pneumatic tires combine pneumatic and solid tires, offering cushioning without flat-tire risk and better handling in difficult terrain. Although they may cost more and be less lightweight, they offer advantages over pneumatic tires, such as less monitoring and no need for inflating.

Non-pneumatic

Semi-pneumatic tires are a hybrid of pneumatic and solid tires, without air tubes, ensuring stability. Non-pneumatic tires are durable, and rough terrain-ready, but they lack cushioning and maneuverability.

Tray

A wheelbarrow tray, also known as a bin, is the part of the wheelbarrow that holds the load. It is usually made of metal, plastic, or wood and is attached to the frame of the wheelbarrow. The size and shape of the tray can vary depending on the wheelbarrow’s intended use.

For example, a wheelbarrow used for gardening may have a shallow tray that is designed to hold light loads, while a wheelbarrow used for construction may have a deep tray that is designed to hold heavy loads.

Removable tray

The majority of the time, removable trays are constructed of metal and are fastened to the wheelbarrow with bolts or pins. As a result, it is simple to take the frame apart for cleaning or storing.

Advantage

Simple to remove for cleaning

If damaged, it is replaceable

can be modified to meet particular demands

Disadvantage

it might cost more than permanent frames

More difficult to assemble and disassemble

Can be more prone to damage

Permanent tray

Fixed trays are non-removable and frequently constructed of molded plastic or metal that has been welded. Permanent trays are more typical on heavy-duty wheelbarrows used in demanding applications like construction.

Advantage

stronger than moveable frames

cheaper than frames that can be removed

easier to put together and take apart

less vulnerable to harm

Disadvantage

can’t be removed for cleaning

Damage that can’t be repaired

cannot be modified to meet certain needs

Handle

The wheelbarrow handle is the part the user holds onto to push or pull the load. It typically has two parallel handles attached to the tray or bucket, made of metal or wood and padded for comfort.

The handles’ length and shape vary depending on their intended use, with longer handles providing more leverage and shorter ones for tight spaces.

They are connected to the tray or bucket via braces, providing stability and preventing shifting or spilling. Some wheelbarrows also have adjustable handles for different heights.important of handle

Wood

Wood handles on wheelbarrows offer comfort, and shock absorption, but are vulnerable to water damage and rot.

Metal

Metal handles on heavy-duty wheelbarrows offer durability and reduce water damage, but they may be slippery and cause hand fatigue.

Composite

Composite handles, made from fiberglass and plastic, offer a lightweight, durable, and comfortable grip, but may be more expensive.

Front brace

Front braces are metal bars that connect handles to a tray or bucket, distributing loads evenly and providing stability. They extend upward and backward, depending on the wheelbarrow’s design.

They work with support legs to maintain stability and prevent tipping over. Front braces also add strength and prevent flexing under heavy loads. Some wheelbarrows may have additional reinforcing cross braces for added strength and stability.

Leg brace

Leg braces are metal bars that connect support legs to a tray or bucket, providing stability to a wheelbarrow. They work in conjunction with the front braces to distribute the load evenly and prevent tipping over.

Some wheelbarrows have additional reinforcing cross braces for added strength and stability. Leg braces can be adjusted to accommodate different loads or adjust stability.

Axel bucket

The wheelbarrow’s axle and bucket are crucial components, ensuring smooth and easy movement and transport of materials and objects.

The axle is a metal rod or shaft, while the bucket is a container for holding the load, typically made of metal or plastic. Together, these components work together to ensure the wheelbarrow’s smooth movement and efficient transportation of materials and objects.

Bearing

Wheelbarrow bearings are small metal components that enable the wheel to rotate smoothly on the axle.

They are typically sealed or unsealed, with sealed bearings being higher-end and maintenance-free. Unsealed bearings are more common in lower-end models and require periodic maintenance to maintain lubrication.

They are less expensive but may need more frequent replacements. The bearings are located on the wheel’s axle, which supports the load and allows the wheel to rotate freely. If worn or damaged, the bearings may cause wobble or difficulty turning, requiring replacement to maintain smooth operation.

Ball bearing

Ball bearings are widely used in wheelbarrows, consisting of small balls rolling between rings, ensuring efficiency and durability.

Roller bearing

Roller bearings are less common but better suited for heavy loads, consisting of cylindrical rollers between rings, offering durability but a higher cost.

Conclusion

A wheelbarrow is a simple yet effective tool for transporting materials and goods. Its basic design includes handles, a tray, and a wheel, operating on levers. Different types of wheels, trays, and handles are essential for smooth movement and efficient transportation. Understanding these components helps you choose the right one for your needs and ensures proper maintenance and repairs.

Outstanding feature

great article

great article

great article

I am always thought about this, appreciate it for putting up.

Techno rozen I do not even understand how I ended up here, but I assumed this publish used to be great

Internet Chicks Awesome! Its genuinely remarkable post, I have got much clear idea regarding from this post . Internet Chicks

hi!,I like your writing so much! share we communicate more approximately your article on AOL? I need an expert on this space to solve my problem. May be that is you! Looking forward to look you.

Tech to Trick Hi there to all, for the reason that I am genuinely keen of reading this website’s post to be updated on a regular basis. It carries pleasant stuff.

Baddiehubs This was beautiful Admin. Thank you for your reflections.

Tech to Force I do not even understand how I ended up here, but I assumed this publish used to be great

I simply could not leave your website prior to suggesting that I actually loved the standard information a person supply on your visitors? Is going to be again incessantly to inspect new posts

I will immediately grab your rss feed as I can’t find your email subscription link or newsletter service. Do you’ve any? Kindly let me know so that I could subscribe. Thanks.

Do you have a spam problem on this blog; I also am a blogger, and I was wondering your situation; many of us have developed some nice methods and we are looking to exchange methods with other folks, why not shoot me an e-mail if interested.

Whats Taking place i am new to this, I stumbled upon this I’ve found It positively useful and it has aided me out loads. I hope to contribute & help other customers like its aided me. Great job.

There is apparently a bundle to identify about this. I consider you made various nice points in features also.

I will right away snatch your rss as I can not in finding your email subscription link or newsletter service. Do you’ve any? Kindly let me recognise in order that I could subscribe. Thanks.

I do agree with all of the ideas you’ve presented in your post. They are very convincing and will definitely work. Still, the posts are too short for starters. Could you please extend them a bit from next time? Thanks for the post.

This really answered my problem, thank you!

I truly appreciate this post. I¦ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thank you again

certainly like your web site but you need to check the spelling on quite a few of your posts. Several of them are rife with spelling problems and I find it very bothersome to tell the truth nevertheless I’ll definitely come back again.

I am no longer positive the place you are getting your info, however good topic. I needs to spend a while studying much more or figuring out more. Thanks for excellent information I used to be looking for this info for my mission.

I have been reading out some of your articles and it’s clever stuff. I will make sure to bookmark your blog.

I want to get across my love for your kindness in support of persons that really need assistance with this one question. Your real dedication to passing the message all over had become extraordinarily important and have continually encouraged individuals just like me to arrive at their endeavors. Your helpful guide signifies a lot to me and a whole lot more to my peers. Regards; from each one of us.

Magnificent website. Lots of helpful info here. I am sending it to a few pals ans additionally sharing in delicious. And of course, thanks in your sweat!

I got good info from your blog

I’ve been browsing online more than three hours today, yet I never found any interesting article like yours. It’s pretty worth enough for me. In my opinion, if all webmasters and bloggers made good content as you did, the web will be much more useful than ever before.

Undeniably believe that which you stated. Your favorite justification seemed to be on the net the simplest thing to be aware of. I say to you, I definitely get irked while people think about worries that they plainly do not know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side effect , people could take a signal. Will likely be back to get more. Thanks

You are my intake, I possess few blogs and occasionally run out from to brand.

Hi my family member! I wish to say that this post is amazing, nice written and include approximately all vital infos. I?¦d like to peer more posts like this .

Family Dollar There is definately a lot to find out about this subject. I like all the points you made

Well I sincerely enjoyed studying it. This tip procured by you is very practical for good planning.

Just what I was looking for, thanks for putting up.

I would like to thnkx for the efforts you have put in writing this web site. I’m hoping the same high-grade blog post from you in the upcoming as well. In fact your creative writing skills has encouraged me to get my own website now. Really the blogging is spreading its wings rapidly. Your write up is a good example of it.

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

I like this post, enjoyed this one regards for posting.

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

Very nice pattern and superb subject material, absolutely nothing else we want : D.

I think this site contains very wonderful pent content content.

Hi there, You’ve performed an excellent job. I’ll certainly digg it and personally suggest to my friends. I’m confident they will be benefited from this website.

Hey! I just wanted to ask if you ever have any issues with hackers? My last blog (wordpress) was hacked and I ended up losing several weeks of hard work due to no backup. Do you have any methods to protect against hackers?

Its excellent as your other articles : D, regards for putting up. “In the spider-web of facts, many a truth is strangled.” by Paul Eldridge.

I’ve been surfing on-line greater than 3 hours today, but I by no means found any interesting article like yours. It is lovely value enough for me. In my opinion, if all webmasters and bloggers made just right content material as you probably did, the web shall be a lot more helpful than ever before.

hi!,I really like your writing very a lot! proportion we be in contact more about your article on AOL? I require an expert on this space to solve my problem. Maybe that’s you! Taking a look forward to look you.

Very interesting info !Perfect just what I was looking for! “Love endures only when the lovers love many things together and not merely each other.” by Walter Lippmann.

Your house is valueble for me. Thanks!…

I’ll immediately take hold of your rss as I can’t in finding your e-mail subscription link or e-newsletter service. Do you have any? Please permit me recognise so that I may subscribe. Thanks.

Saved as a favorite, I really like your blog!

I truly appreciate this post. I’ve been looking all over for this! Thank goodness I found it on Bing. You have made my day! Thank you again

Good day! Do you use Twitter? I’d like to follow you if that would be ok. I’m undoubtedly enjoying your blog and look forward to new posts.

Its excellent as your other content : D, thanks for posting.

Throughout this grand scheme of things you get a B+ with regard to effort and hard work. Where you actually lost me personally was on the details. You know, people say, the devil is in the details… And that couldn’t be much more correct at this point. Having said that, allow me tell you just what did work. The authoring is definitely very engaging and that is most likely the reason why I am making the effort to opine. I do not really make it a regular habit of doing that. Secondly, although I can see the leaps in reasoning you come up with, I am not really certain of just how you seem to unite your details which inturn produce the conclusion. For right now I will, no doubt subscribe to your position however trust in the future you link your facts much better.

You got a very fantastic website, Gladiolus I detected it through yahoo.

I dugg some of you post as I cogitated they were extremely helpful very helpful

Hey there are using WordPress for your site platform? I’m new to the blog world but I’m trying to get started and create my own. Do you need any coding knowledge to make your own blog? Any help would be greatly appreciated!

hey there and thank you for your info – I’ve certainly picked up anything new from right here. I did however expertise a few technical points using this website, since I experienced to reload the site lots of times previous to I could get it to load correctly. I had been wondering if your web hosting is OK? Not that I’m complaining, but sluggish loading instances times will often affect your placement in google and can damage your high-quality score if advertising and marketing with Adwords. Well I’m adding this RSS to my e-mail and could look out for a lot more of your respective intriguing content. Make sure you update this again soon..

Hello very cool blog!! Man .. Excellent .. Superb .. I will bookmark your web site and take the feeds alsoKI’m happy to find a lot of useful info here within the submit, we’d like develop more strategies on this regard, thanks for sharing. . . . . .

Just wanna comment that you have a very decent site, I enjoy the style it really stands out.

Thanks for another fantastic post. Where else could anyone get that type of information in such an ideal way of writing? I’ve a presentation next week, and I’m on the look for such information.

I always was concerned in this subject and still am, appreciate it for putting up.

There are some fascinating points in time in this article however I don’t know if I see all of them middle to heart. There is some validity but I will take hold opinion till I look into it further. Good article , thanks and we wish extra! Added to FeedBurner as effectively

Hmm it seems like your blog ate my first comment (it was super long) so I guess I’ll just sum it up what I submitted and say, I’m thoroughly enjoying your blog. I as well am an aspiring blog writer but I’m still new to everything. Do you have any recommendations for inexperienced blog writers? I’d genuinely appreciate it.

You have observed very interesting points! ps nice site.

Some times its a pain in the ass to read what people wrote but this internet site is real user pleasant! .

I truly enjoy looking at on this site, it has got superb blog posts. “He who sees the truth, let him proclaim it, without asking who is for it or who is against it.” by Henry George.

Awsome website! I am loving it!! Will be back later to read some more. I am bookmarking your feeds also.

I’m impressed, I have to say. Actually rarely do I encounter a weblog that’s both educative and entertaining, and let me let you know, you have hit the nail on the head. Your concept is excellent; the issue is one thing that not enough individuals are speaking intelligently about. I am very comfortable that I stumbled across this in my search for one thing relating to this.

I carry on listening to the reports lecture about getting free online grant applications so I have been looking around for the best site to get one. Could you tell me please, where could i acquire some?

I enjoy you because of your own labor on this blog. My niece take interest in working on research and it’s simple to grasp why. A lot of people learn all relating to the dynamic method you present rewarding thoughts through the website and as well inspire response from other individuals on the concern and our favorite daughter is certainly learning a lot. Have fun with the remaining portion of the year. You are always carrying out a first class job.

I am delighted that I detected this weblog, exactly the right information that I was looking for! .

I couldn’t resist commenting

Hey there just wanted to give you a quick heads up and let you know a few of the images aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same outcome.

Thank you for another informative site. Where else could I get that type of info written in such a perfect way? I’ve a project that I’m just now working on, and I have been on the look out for such info.

I love it when people come together and share opinions, great blog, keep it up.

Real wonderful info can be found on web blog. “I know of no great men except those who have rendered great service to the human race.” by Francois Marie Arouet Voltaire.

Great write-up, I¦m normal visitor of one¦s website, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

It¦s actually a nice and helpful piece of info. I¦m glad that you simply shared this helpful info with us. Please keep us informed like this. Thank you for sharing.

Howdy very cool web site!! Man .. Beautiful .. Amazing .. I will bookmark your web site and take the feeds alsoKI am glad to search out numerous useful information right here within the publish, we’d like work out more strategies on this regard, thank you for sharing. . . . . .

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

Thank you for all of the labor on this web page. My mum really loves conducting research and it is easy to see why. Most of us learn all relating to the dynamic method you convey very useful techniques through this website and even cause contribution from visitors on this concept and our favorite child is in fact studying a lot. Take advantage of the remaining portion of the year. Your conducting a very good job.

I like what you guys are up also. Such clever work and reporting! Keep up the excellent works guys I have incorporated you guys to my blogroll. I think it will improve the value of my site :).

I like this website so much, bookmarked. “American soldiers must be turned into lambs and eating them is tolerated.” by Muammar Qaddafi.

Thanks, I have just been searching for information about this subject for a long time and yours is the greatest I’ve came upon so far. However, what concerning the bottom line? Are you sure concerning the supply?

Hey very nice website!! Man .. Excellent .. Wonderful .. I’ll bookmark your site and take the feeds alsoKI am satisfied to find a lot of helpful information here within the put up, we want work out more strategies in this regard, thanks for sharing. . . . . .

Thank you, I’ve recently been looking for information about this subject for ages and yours is the best I’ve discovered till now. But, what about the bottom line? Are you sure about the source?

Thanks for some other informative website. Where else could I am getting that kind of information written in such an ideal manner? I have a undertaking that I am simply now operating on, and I have been at the look out for such info.

Cool blog! Is your theme custom made or did you download it from somewhere? A design like yours with a few simple tweeks would really make my blog stand out. Please let me know where you got your theme. Appreciate it

I’ve recently started a website, the info you provide on this site has helped me tremendously. Thanks for all of your time & work. “If you see a snake, just kill it. Don’t appoint a committee on snakes.” by H. Ross Perot.

I’ll immediately grab your rss as I can’t find your email subscription link or e-newsletter service. Do you have any? Please let me know so that I could subscribe. Thanks.

Fantastic web site. Plenty of helpful info here. I am sending it to several friends ans additionally sharing in delicious. And obviously, thanks in your effort!

Pretty section of content. I just stumbled upon your weblog and in accession capital to assert that I get actually enjoyed account your blog posts. Anyway I will be subscribing to your feeds and even I achievement you access consistently rapidly.

Do you mind if I quote a couple of your articles as long as I provide credit and sources back to your blog? My blog is in the exact same niche as yours and my users would genuinely benefit from some of the information you present here. Please let me know if this alright with you. Many thanks!

Heya i am for the first time here. I came across this board and I in finding It truly useful & it helped me out a lot. I hope to present something again and help others like you helped me.

I’d have to examine with you here. Which is not one thing I usually do! I take pleasure in reading a post that may make folks think. Additionally, thanks for permitting me to comment!

I think other web-site proprietors should take this website as an model, very clean and fantastic user genial style and design, let alone the content. You’re an expert in this topic!

Hi there! This is my first visit to your blog! We are a collection of volunteers and starting a new project in a community in the same niche. Your blog provided us beneficial information to work on. You have done a wonderful job!

Hi my friend! I want to say that this article is amazing, nice written and include approximately all important infos. I would like to see more posts like this.

Some truly interesting points you have written.Aided me a lot, just what I was searching for : D.

Some genuinely interesting information, well written and generally user friendly.

I like this post, enjoyed this one thank you for posting. “He removes the greatest ornament of friendship, who takes away from it respect.” by Cicero.

Please let me know if you’re looking for a writer for your blog. You have some really great posts and I believe I would be a good asset. If you ever want to take some of the load off, I’d love to write some articles for your blog in exchange for a link back to mine. Please blast me an e-mail if interested. Regards!

It’s in point of fact a great and helpful piece of info. I’m satisfied that you simply shared this useful info with us. Please stay us informed like this. Thank you for sharing.

I admire your work, regards for all the great blog posts.

I went over this internet site and I conceive you have a lot of fantastic info , saved to favorites (:.

Youre so cool! I dont suppose Ive read anything like this before. So nice to search out somebody with some original ideas on this subject. realy thank you for beginning this up. this web site is something that’s needed on the internet, someone with a bit of originality. helpful job for bringing something new to the internet!

I have been exploring for a little bit for any high quality articles or blog posts in this sort of space . Exploring in Yahoo I at last stumbled upon this site. Reading this information So i am happy to express that I have a very good uncanny feeling I came upon exactly what I needed. I so much surely will make certain to do not put out of your mind this web site and provides it a look on a relentless basis.

I don’t commonly comment but I gotta say thankyou for the post on this perfect one : D.

You made some good points there. I looked on the internet for the subject and found most persons will go along with with your site.

I would like to thnkx for the efforts you’ve put in writing this site. I am hoping the same high-grade web site post from you in the upcoming also. In fact your creative writing skills has inspired me to get my own website now. Actually the blogging is spreading its wings quickly. Your write up is a good example of it.

I’ve recently started a web site, the information you provide on this web site has helped me greatly. Thanks for all of your time & work.

Wow! This could be one particular of the most useful blogs We have ever arrive across on this subject. Actually Wonderful. I’m also an expert in this topic therefore I can understand your effort.

I’m really enjoying the theme/design of your website. Do you ever run into any web browser compatibility problems? A few of my blog visitors have complained about my site not working correctly in Explorer but looks great in Firefox. Do you have any tips to help fix this issue?

Good day! Do you use Twitter? I’d like to follow you if that would be ok. I’m absolutely enjoying your blog and look forward to new posts.

Great wordpress blog here.. It’s hard to find quality writing like yours these days. I really appreciate people like you! take care

I do not even know how I ended up here, but I thought this post was good. I do not know who you are but certainly you are going to a famous blogger if you are not already 😉 Cheers!

Hello, i read your blog from time to time and i own a similar one and i was just wondering if you get a lot of spam comments? If so how do you stop it, any plugin or anything you can recommend? I get so much lately it’s driving me mad so any help is very much appreciated.

I dugg some of you post as I cogitated they were extremely helpful very beneficial

I do agree with all of the ideas you’ve presented in your post. They are really convincing and will certainly work. Still, the posts are too short for newbies. Could you please extend them a bit from next time? Thanks for the post.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

I am glad that I discovered this web blog, just the right information that I was looking for! .

Aroma Sensei I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

Ezippi Nice post. I learn something totally new and challenging on websites

Back Magazin I very delighted to find this internet site on bing, just what I was searching for as well saved to fav

Pretty! This was a really wonderful post. Thank you for your provided information.

You could certainly see your skills within the paintings you write. The sector hopes for even more passionate writers such as you who aren’t afraid to say how they believe. At all times follow your heart.

Sweet internet site, super layout, rattling clean and employ pleasant.

Some truly great blog posts on this site, regards for contribution.

What’s up, everything is going well here and ofcourse every one is sharing data, that’s truly fine, keep up writing.

my webpage: https://Penzu.com/p/6bb0260c

Thank you for the auspicious writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how can we communicate

Do you have a spam issue on this website; I also am a blogger, and I was wondering your situation; many of us have developed some nice practices and we are looking to exchange techniques with other folks, please shoot me an email if interested.

hiI like your writing so much share we be in contact more approximately your article on AOL I need a specialist in this area to resolve my problem Maybe that is you Looking ahead to see you

Noodlemagazine Nice post. I learn something totally new and challenging on websites

I think other website owners should take this internet site as an example , very clean and fantastic user genial style and design.

Attractive component of content. I just stumbled upon your blog and in accession capital to claim that I get in fact enjoyed account your blog posts. Anyway I’ll be subscribing in your feeds and even I achievement you get admission to persistently fast.

I’m really inspired with your writing abilities and also with the format in your weblog. Is that this a paid theme or did you modify it your self? Either way stay up the excellent high quality writing, it is rare to look a nice blog like this one nowadays..

Heya i am for the first time here. I came across this board and I find It really useful & it helped me out

much. I hope to give something back and aid others like

you helped me.

Oh my goodness! a tremendous article dude. Thanks However I am experiencing subject with ur rss . Don’t know why Unable to subscribe to it. Is there anybody getting identical rss downside? Anybody who knows kindly respond. Thnkx

What i do not realize is in reality how you’re no longer actually much more well-appreciated than you may be now. You are so intelligent. You know therefore significantly in relation to this matter, produced me for my part imagine it from numerous numerous angles. Its like women and men are not interested except it is something to accomplish with Woman gaga! Your personal stuffs excellent. At all times care for it up!

Some really excellent info , Gladiolus I detected this. “We go where our vision is.” by Joseph Murphy.

It?¦s truly a great and useful piece of info. I am glad that you simply shared this useful information with us. Please stay us informed like this. Thank you for sharing.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

Ethical Considerations When Upgradating Your Wheelbarrow – Should You Prioritize Sustainability Over Convenience? Consider the environmental impact and labor implications of choosing eco-friendly materials or automated features. Is it ethical to upgrade your wheelbarrow with advanced technology at the cost of traditional craftsmanship and local economies?

Проблемы с сантехникой? Мы осуществляем установку и замену в Минске с гарантией надежности. Наши практикующие мастера готовы провести чистку. Узнайте больше на монтаж сантехники минск .

Кайт Хургада

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

With thanks, I value it!

casino royale smotret online https://linkscasino.info/esports-betting/ tropicana online casino app

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Букмекерская контора Leonbets предоставляет игрокам удобный доступ к пари через современный интерфейс и широкий выбор событий. На сайте [url=https://www.goha.ru/leon-bet-leonbets-zerkalo-rabochee-registraciya-obzor-sajta-4wqP3y/]леон бет[/url] предлагает выгодные коэффициенты, бонусы для новичков и эксклюзивные акции. Здесь можно делать ставки на свыше 20 видов спорта, включая топовые соревнования и eSports. Программа лояльности позволяет собирать очки (леоны), которые конвертируются на призы, а официальная аппликация обеспечивает быстрый доступ к возможностям.

Для игроков из России, где официальная страница может быть ограничен, существует [url=https://www.goha.ru/leon-bet-leonbets-zerkalo-rabochee-registraciya-obzor-sajta-4wqP3y/]бк леон[/url] обеспечивающее полноценный доступ к аккаунту и функциям платформы. Зеркало повторяет оригинальный сайт, сохраняя все персональную информацию, и не содержит лишнего контента. Минимальная ставка составляет лишь 10 рублей, а транзакции доступен на различные платежные системы с учетом комиссионных сборов до 5%. Благодаря таким преимуществам, Leonbets прочно удерживает среди лидеров среди букмекеров России по популярности.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

кайт египет

кайт хургада кайт хургада

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

apple macbook pro 15 i7 ноутбук apple macbook air 15 512

toto 368

vibracion de motor

Aparatos de equilibrado: clave para el rendimiento fluido y productivo de las dispositivos.

En el campo de la tecnología avanzada, donde la productividad y la estabilidad del aparato son de máxima significancia, los aparatos de calibración cumplen un papel crucial. Estos sistemas especializados están creados para equilibrar y asegurar componentes giratorias, ya sea en herramientas manufacturera, medios de transporte de movilidad o incluso en equipos domésticos.

Para los expertos en mantenimiento de dispositivos y los técnicos, trabajar con sistemas de calibración es crucial para proteger el funcionamiento fluido y estable de cualquier sistema móvil. Gracias a estas soluciones innovadoras modernas, es posible reducir significativamente las vibraciones, el zumbido y la presión sobre los soportes, aumentando la vida útil de piezas caros.

Asimismo significativo es el papel que tienen los aparatos de equilibrado en la servicio al consumidor. El soporte técnico y el conservación regular empleando estos dispositivos posibilitan ofrecer prestaciones de óptima calidad, aumentando la agrado de los usuarios.

Para los titulares de emprendimientos, la financiamiento en unidades de equilibrado y sensores puede ser fundamental para aumentar la efectividad y eficiencia de sus dispositivos. Esto es principalmente relevante para los dueños de negocios que manejan modestas y intermedias organizaciones, donde cada elemento es relevante.

Por otro lado, los dispositivos de ajuste tienen una extensa aplicación en el ámbito de la seguridad y el monitoreo de excelencia. Permiten identificar probables defectos, evitando mantenimientos caras y problemas a los sistemas. Además, los resultados generados de estos aparatos pueden emplearse para optimizar sistemas y aumentar la reconocimiento en plataformas de búsqueda.

Las campos de utilización de los equipos de equilibrado comprenden numerosas industrias, desde la manufactura de ciclos hasta el supervisión del medio ambiente. No interesa si se habla de enormes manufacturas manufactureras o reducidos locales domésticos, los equipos de balanceo son indispensables para promover un operación efectivo y sin interrupciones.

Equilibrado

Equipos de equilibrado: fundamental para el desempeño uniforme y efectivo de las dispositivos.

En el campo de la tecnología contemporánea, donde la productividad y la confiabilidad del aparato son de alta trascendencia, los aparatos de calibración juegan un tarea esencial. Estos sistemas especializados están desarrollados para ajustar y asegurar componentes móviles, ya sea en dispositivos productiva, vehículos de movilidad o incluso en equipos caseros.

Para los técnicos en reparación de equipos y los especialistas, operar con aparatos de equilibrado es crucial para promover el funcionamiento uniforme y seguro de cualquier dispositivo dinámico. Gracias a estas soluciones modernas innovadoras, es posible reducir notablemente las movimientos, el zumbido y la esfuerzo sobre los soportes, aumentando la longevidad de partes valiosos.

También trascendental es el función que juegan los sistemas de equilibrado en la asistencia al consumidor. El ayuda especializado y el mantenimiento continuo utilizando estos sistemas posibilitan brindar servicios de gran estándar, mejorando la bienestar de los clientes.

Para los titulares de negocios, la financiamiento en sistemas de calibración y dispositivos puede ser importante para incrementar la efectividad y desempeño de sus dispositivos. Esto es principalmente trascendental para los dueños de negocios que manejan modestas y modestas empresas, donde cada punto es relevante.

Asimismo, los aparatos de ajuste tienen una vasta implementación en el campo de la seguridad y el control de estándar. Permiten encontrar probables defectos, evitando mantenimientos costosas y daños a los dispositivos. Además, los datos extraídos de estos sistemas pueden usarse para mejorar sistemas y aumentar la exposición en buscadores de consulta.

Las zonas de implementación de los dispositivos de balanceo abarcan múltiples ramas, desde la manufactura de vehículos de dos ruedas hasta el supervisión de la naturaleza. No influye si se trata de enormes fabricaciones industriales o pequeños locales domésticos, los dispositivos de balanceo son necesarios para proteger un funcionamiento óptimo y sin presencia de detenciones.

Ровный, плотный и здоровый газон уже через несколько часов – это реально! Если вам нужна [url=https://greenhistory.ru/tseny/gazon_rulonniy]укладка рулонного газона под ключ москва[/url], обращайтесь в Greenhistory.ru. Мы подготовим почву, привезем свежий газон и уложим его так, чтобы он прижился максимально быстро. Оставьте заявку прямо сейчас!

Нужны деньги прямо сейчас? [url=https://postabank.ru/]Взять кредит на карту[/url] стало проще для молодежи от 18 лет. Современные МФО предлагают честные условия: только паспорт, фиксированная ставка до 0.8% и быстрое одобрение. Решайте финансовые вопросы легко и быстро, где бы вы ни находились.

кайт школа хургада

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

GENDANG4D

https://химчисткамебели.online

https://1domovoy.ru

Your article helped me a lot, is there any more related content? Thanks!

https://cemstroy-t68.ru

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

娛樂城大解析

娛樂城,通常指的是一個線上賭博平台,提供各種娛樂遊戲,如賭場遊戲、體育博彩、電子遊戲等。這些平台讓玩家可以在網路上進行賭博,而不需要親自前往實體賭場。娛樂城通常包含了各式各樣的遊戲選項,例如百家樂、輪盤、老虎機、撲克等,並且透過即時娛樂、直播等技術,提升了玩家的沉浸感和互動性。現今的娛樂城大多數已經支援手機和桌面端的多平台操作,讓玩家可以隨時隨地參與遊戲,這樣的便利性使得它們受到全球玩家的青睞。此外,娛樂城也會推出不同的優惠活動、註冊獎金和忠誠計劃,吸引新用戶並保持老用戶的活躍度。然而,娛樂城的風險也不可忽視。由於賭博本身具有高度的娛樂性,但也存在可能的成癮問題。多數國家對於線上賭博有著嚴格的法律規範,玩家在選擇娛樂城平台時,應該格外留意平台的合法性和安全性,以避免陷入詐騙或遭遇其他法律風險。因此,理性投注並了解相關法律是每位玩家應該保持的基本態度。

Смартфон стал тормозить после падения? Срочный [url=https://mobile-worker.ru/remont-iphone-x.html]ремонт iphone 10[/url] в авторизованном сервисном центре поможет восстановить работу любимого устройства. Квалифицированные мастера проведут диагностику и выполнят ремонт любой сложности в кратчайшие сроки.

Нужен срочный ремонт техники? Mobile-Worker на Коломенской – ваш надёжный помощник! Более 10 лет наша мастерская успешно решает любые проблемы с телефонами, планшетами и ноутбуками. Опытные мастера проведут бесплатную диагностику и выполнят ремонт в день обращения с гарантией 60 дней.

[url=https://images.google.ru/url?q=https://expl0it.ru/]займ на карту 0 процентов[/url] – отличная возможность получить деньги без переплат! Этот список МФО предлагает беспроцентные займы. Деньги на карту до 50 000 рублей без отказов, доступно онлайн 24/7.

https://kazhdogopravo.ru

娛樂城,通常指的是一個線上賭博平台,提供各種娛樂遊戲,如賭場遊戲、體育博彩、電子遊戲等。這些平台讓玩家可以在網路上進行賭博,而不需要親自前往實體賭場。娛樂城通常包含了各式各樣的遊戲選項,例如百家樂、輪盤、老虎機、撲克等,並且透過即時娛樂、直播等技術,提升了玩家的沉浸感和互動性。現今的娛樂城大多數已經支援手機和桌面端的多平台操作,讓玩家可以隨時隨地參與遊戲,這樣的便利性使得它們受到全球玩家的青睞。此外,娛樂城也會推出不同的優惠活動、註冊獎金和忠誠計劃,吸引新用戶並保持老用戶的活躍度。然而,娛樂城的風險也不可忽視。由於賭博本身具有高度的娛樂性,但也存在可能的成癮問題。多數國家對於線上賭博有著嚴格的法律規範,玩家在選擇娛樂城平台時,應該格外留意平台的合法性和安全性,以避免陷入詐騙或遭遇其他法律風險。因此,理性投注並了解相關法律是每位玩家應該保持的基本態度。

plm

Best Practices for Implementing PLM Software in Fashion Brands

The fashion industry is a dynamic and competitive landscape, where brands must constantly innovate to stay ahead. To meet consumer demands, reduce costs, and streamline operations, many fashion companies are turning to Product Lifecycle Management (PLM) software. However, successful implementation of PLM requires more than just purchasing the right tool—it demands strategic planning, team involvement, and a clear understanding of organizational goals.

Why PLM Matters in Fashion

Fashion brands operate in a fast-paced environment, where trends change rapidly, and supply chains span the globe. From design to production, every step in the product lifecycle must be optimized for efficiency and accuracy. PLM software provides a centralized platform that integrates data, improves collaboration, and enhances decision-making. By adopting PLM, brands can:

Streamline product development processes

Improve communication between teams and partners

Reduce time-to-market

Enhance supply chain visibility

Minimize errors and waste

However, realizing these benefits depends on how effectively the software is implemented.

Key Steps for Successful PLM Implementation

Define Clear Objectives

Before implementing PLM, brands must identify their specific needs and goals. Are you looking to improve design efficiency? Reduce production costs? Or enhance supplier collaboration? Clearly defined objectives will guide the implementation process and ensure alignment with business priorities.

Engage Stakeholders Early

PLM impacts multiple departments, including design, production, procurement, and marketing. Involving key stakeholders from the outset ensures buy-in and fosters collaboration. It also helps tailor the system to meet diverse requirements and workflows.

Choose the Right Solution

Not all PLM systems are created equal. Some are better suited for large enterprises, while others cater to smaller brands. Evaluate vendors based on features, scalability, ease of use, and integration capabilities. Cloud-based PLM solutions, for instance, offer flexibility and real-time access, making them ideal for global teams.

Focus on Data Migration and Standardization

Transitioning to PLM often involves migrating existing data into the new system. This process can be complex, so it’s essential to clean and standardize data beforehand. Establishing consistent naming conventions, measurement units, and file formats will prevent confusion and ensure smooth operations.

Provide Comprehensive Training

Even the most advanced PLM system won’t deliver results if users don’t know how to leverage its features. Provide hands-on training sessions and create user-friendly guides to help employees adapt quickly. Encourage feedback during the initial rollout to address challenges and refine workflows.

Monitor Progress and Iterate

Implementation doesn’t end after go-live. Regularly monitor performance metrics, gather user feedback, and make necessary adjustments. Continuous improvement ensures the system evolves alongside your brand’s needs.

Real-World Impact of PLM in Fashion

Consider the success stories of brands that have embraced PLM. For example, one leading apparel company reduced its product development cycle by 30% after implementing a cloud-based PLM solution. Another brand improved supplier collaboration, resulting in faster production timelines and reduced material waste. These examples demonstrate the transformative power of PLM when implemented strategically.

Conclusion

Implementing PLM software is a significant investment, but the potential rewards far outweigh the challenges. By following best practices—such as setting clear goals, engaging stakeholders, and providing robust training—fashion brands can unlock the full potential of PLM. As the industry continues to evolve, those who embrace technology like PLM will not only survive but thrive in an increasingly competitive market.

For fashion brands ready to take the next step, PLM isn’t just a tool—it’s a pathway to innovation, efficiency, and long-term success.

By Tatiana Kochergina | Published March 12, 2025

This article provides actionable insights for fashion brands considering PLM software adoption. By showcasing real-world applications and emphasizing strategic planning, it positions PLM as a critical enabler of growth and innovation in the fashion industry.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

plm

Best Practices for Implementing PLM Software in Fashion Brands

The fashion industry is a dynamic and competitive landscape, where brands must constantly innovate to stay ahead. To meet consumer demands, reduce costs, and streamline operations, many fashion companies are turning to Product Lifecycle Management (PLM) software. However, successful implementation of PLM requires more than just purchasing the right tool—it demands strategic planning, team involvement, and a clear understanding of organizational goals.

Why PLM Matters in Fashion

Fashion brands operate in a fast-paced environment, where trends change rapidly, and supply chains span the globe. From design to production, every step in the product lifecycle must be optimized for efficiency and accuracy. PLM software provides a centralized platform that integrates data, improves collaboration, and enhances decision-making. By adopting PLM, brands can:

Streamline product development processes

Improve communication between teams and partners

Reduce time-to-market

Enhance supply chain visibility

Minimize errors and waste

However, realizing these benefits depends on how effectively the software is implemented.

Key Steps for Successful PLM Implementation

Define Clear Objectives

Before implementing PLM, brands must identify their specific needs and goals. Are you looking to improve design efficiency? Reduce production costs? Or enhance supplier collaboration? Clearly defined objectives will guide the implementation process and ensure alignment with business priorities.

Engage Stakeholders Early

PLM impacts multiple departments, including design, production, procurement, and marketing. Involving key stakeholders from the outset ensures buy-in and fosters collaboration. It also helps tailor the system to meet diverse requirements and workflows.

Choose the Right Solution

Not all PLM systems are created equal. Some are better suited for large enterprises, while others cater to smaller brands. Evaluate vendors based on features, scalability, ease of use, and integration capabilities. Cloud-based PLM solutions, for instance, offer flexibility and real-time access, making them ideal for global teams.

Focus on Data Migration and Standardization

Transitioning to PLM often involves migrating existing data into the new system. This process can be complex, so it’s essential to clean and standardize data beforehand. Establishing consistent naming conventions, measurement units, and file formats will prevent confusion and ensure smooth operations.

Provide Comprehensive Training

Even the most advanced PLM system won’t deliver results if users don’t know how to leverage its features. Provide hands-on training sessions and create user-friendly guides to help employees adapt quickly. Encourage feedback during the initial rollout to address challenges and refine workflows.

Monitor Progress and Iterate

Implementation doesn’t end after go-live. Regularly monitor performance metrics, gather user feedback, and make necessary adjustments. Continuous improvement ensures the system evolves alongside your brand’s needs.

Real-World Impact of PLM in Fashion

Consider the success stories of brands that have embraced PLM. For example, one leading apparel company reduced its product development cycle by 30% after implementing a cloud-based PLM solution. Another brand improved supplier collaboration, resulting in faster production timelines and reduced material waste. These examples demonstrate the transformative power of PLM when implemented strategically.

Conclusion

Implementing PLM software is a significant investment, but the potential rewards far outweigh the challenges. By following best practices—such as setting clear goals, engaging stakeholders, and providing robust training—fashion brands can unlock the full potential of PLM. As the industry continues to evolve, those who embrace technology like PLM will not only survive but thrive in an increasingly competitive market.

For fashion brands ready to take the next step, PLM isn’t just a tool—it’s a pathway to innovation, efficiency, and long-term success.

By Tatiana Kochergina | Published March 12, 2025

This article provides actionable insights for fashion brands considering PLM software adoption. By showcasing real-world applications and emphasizing strategic planning, it positions PLM as a critical enabler of growth and innovation in the fashion industry.

https://imcongroup.ru

https://ceramodecol.ru

hoki1881

mlb直播

https://chelstg.ru

戰神賽特

「戰神賽特」— 2025年最火爆的老虎機,等你來挑戰!

如果你正在尋找一款高賠率、刺激又充滿神秘感的老虎機遊戲,那麼「戰神賽特」絕對是你的最佳選擇!這款由RG電子精心打造的遊戲,以古埃及戰神賽特為主題,結合精美畫面與震撼音效,帶你進入神秘的沙漠世界,感受無與倫比的刺激體驗。

為何玩家瘋狂愛上戰神賽特?

超狂賠率 51,000 倍:一轉瞬間,財富翻倍不是夢

高RTP達96.89%:更高勝率,更多機會贏得大獎

獨特遊戲機制:掉落消除+獎金購買,玩法多樣更刺激

極致視聽享受:古埃及風格設計+震撼音效,讓你完全沉浸其中

無論你是老虎機高手還是新手玩家,「戰神賽特」都能帶給你前所未有的遊戲體驗!快來挑戰戰神,贏取屬於你的豐厚獎勵!

you’re truly a good webmaster. The website loading velocity is amazing. It kind of feels that you’re doing any distinctive trick. Moreover, The contents are masterwork. you’ve done a excellent activity on this subject!

снятие ломки наркология

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

戰神賽特

「戰神賽特」— 2025年最火爆的老虎機,等你來挑戰!

如果你正在尋找一款高賠率、刺激又充滿神秘感的老虎機遊戲,那麼「戰神賽特」絕對是你的最佳選擇!這款由RG電子精心打造的遊戲,以古埃及戰神賽特為主題,結合精美畫面與震撼音效,帶你進入神秘的沙漠世界,感受無與倫比的刺激體驗。

為何玩家瘋狂愛上戰神賽特?

超狂賠率 51,000 倍:一轉瞬間,財富翻倍不是夢

高RTP達96.89%:更高勝率,更多機會贏得大獎

獨特遊戲機制:掉落消除+獎金購買,玩法多樣更刺激

極致視聽享受:古埃及風格設計+震撼音效,讓你完全沉浸其中

無論你是老虎機高手還是新手玩家,「戰神賽特」都能帶給你前所未有的遊戲體驗!快來挑戰戰神,贏取屬於你的豐厚獎勵!

кайт школа хургада

кайтсёрфинг в станице благовещенской

novosti24chasa.ru – ваш надежный источник актуальных новостей! Мы оперативно освещаем события политики, экономики, технологий, спорта и культуры. Всегда свежие материалы, объективные аналитические обзоры и эксклюзивные интервью. Будьте в курсе главного – следите за новостями вместе с нами!

кайт египет

Just want too say your article is as amazing. The clarity in yourr post is simply nice and i can asdsume you’re

an expert on this subject. Fine with your permission let me to grab your RSS feed to

keep updated with forthcoming post. Thanks a million annd please continue thhe

rewarding work. https://menbehealth.wordpress.com/

Just want too say yyour article is as amazing.

The clarity in your post is simply nide and i cann assume you’re an expert onn his subject.

Fine with your permission let me to grab your RSS feed to keep updated withh forthcoming post.

Thawnks a million and please continue thee rewarding work. https://menbehealth.wordpress.com/

кайт египет

Medic ORL Sibiu

Dr. Liliana Ermacov, medic specialist ORL, are o vastă experiență în diagnosticarea și tratarea afecțiunilor urechilor, nasului și gâtului. Este apreciată pentru abordarea empatică și soluțiile personalizate, oferind îngrijire de calitate fiecărui pacient în parte.

кайт школа анапа

кайт египет

кайт эльгуна

iPhone 11 iphone 14 max

кайт хургада

Строительные бытовки

Бытовки и модульные здания: эффективное решение для клиентских нужд

Контейнеры и передвижные помещения помогают оборудовать рабочее пространство, помещение для хранения или временную постройку. Команда гарантируем конструкции, которые удовлетворяют высоким стандартам безопасности и функциональности.

Преимущества

Надёжность. Все контейнеры созданы из материалов, стойких к давлению и климатическим факторам.

Быстрая поставка. Постройка перевозится в пределах 1–2 суток после оформления заказа.

Персонализация. Осуществляется компоновка термоизоляции, электропроводки или системы проветривания.

Зоны действия

На строительных площадках для накопления материалов или устройства комнаты для рабочих.

Во время акций для оборудования пункта контроля или хранилища техники.

В качестве временных офисов или операционных штабов.

Выгоды

Ускорение процессов. Не нужно возводить временные сооружения.

Функциональность. Обстановка, которые улучшают эффективность работы бригады.

Вариативность. Решение аренды или долгосрочного использования под индивидуальные нужды и бюджет.

Пример использования

Фирма-застройщик использовала блок-контейнер для организации склада инструментов и помещения для персонала. Модуль была привезена за один день, с улучшенной термоизоляцией. Партнёр подчеркнул на улучшение обстановки и отсутствие простоев.

Как начать сотрудничество

Для подачи заявки нужно обратиться с нами. Выделим полные данные, поможем выбрать оптимальное решение и выполним перевозку.

iphone download iPhone 11

кайтсёрфинг в хургаде

оценка дом участок сбербанк http://ocenka-zagorod.ru

типографии спб печать типография где спб

типография а4 цена типография сколько

услуги грузчиков перевозки заказать грузчиков

помощь при переезде грузчики https://isilkul.standart-express.ru

грузоперевозки услуги грузчиков https://toguchin.standart-express.ru

Vous trouverez sur RSTFOOT une large gamme de maillots de football à prix réduits pour toutes les équipes. Expert depuis 10 ans, le site propose des maillots neufs et vintage qu’on peut de personnalisation. Leur atout : des prix très compétitifs, des tissus résistants et livraison sous 15 jours. Parfait pour supporters à la recherche un look officiel sans se ruiner.

Модули и блок-контейнеры: практичное вариант для пользовательских задач

Модули и временные конструкции способствуют наладить рабочее пространство, склад или временный домик. Мы обеспечиваем здания, которые подходят профессиональным нормам надёжности и удобства.

Характеристики

Надёжность. Каждая вагончики изготовлены из компонентов, надёжных к нагрузкам и климатическим факторам.

Оперативность транспортировки. Объект доставляется в срок 1–2 рабочих дней после подтверждения заявки.

Гибкая настройка. Реализуется добавление защиты от холода, электрики или приточной системы.

Области применения

На строительных объектах для хранения инструментов или организации комнаты отдыха.

Во время событий для организации стойки приёма или помещения для инвентаря.

В качестве временных офисов или центров координации.

Достоинства

Оптимизация времени. Нет необходимости создавать временные конструкции.

Функциональность. Атмосфера, которые повышают эффективность работы персонала.

Адаптивность. Опция краткосрочного пользования или долгосрочного использования под разные периоды и денежные средства.

Пример использования

Строительный подряд внедрила модульное здание для организации склада инструментов и помещения для персонала. Модуль была транспортирована за день, с специальным утеплением. Заказчик выделил на улучшение обстановки и минимизацию задержек.

Как оформить заказ

Для подачи заявки следует обратиться с нами. Дадим всю необходимую информацию, окажем помощь найти идеальный выбор и выполним доставку.

Продажа путёвок https://camp-centr.com/camps/type/lager-na-more.html. Спортивные, творческие и тематические смены. Весёлый и безопасный отдых под присмотром педагогов и аниматоров. Бронируйте онлайн!

офсетная печать визиток печать визиток а4

магазин аккаунтов социальных сетей покупка аккаунтов соц сетей

Выполняем качественное проектирование итп под ключ. Энергоэффективные решения для домов, офисов, промышленных объектов. Гарантия, соблюдение СНиП и точные сроки!

печать бланков https://pechat-blankov-spb.ru

печать на пластиковых папках https://pechat-papok.ru

Thank you for some other magnificent article. Where else may anyone get that type of info in such an ideal approach of writing? I’ve a presentation next week, and I’m at the look for such information.

промокод либет казино

печать картин на холсте pechat-na-holste2.ru

dtf печать на футболках dtf печать стоимость

широкоформатная печать спб https://shirokoformatnaya-pechat-spb.ru

Hi, I wish for to subscribe for this weblog to take most up-to-date updates, so where can i do it please help out.

1xbet free bet promo code india

кайт школа хургада

оптимизация сайта цена цена поисковая оптимизация сайта

заказать раскрутку сайта https://prodvizheniestatya.ru

kantor bola

продвижение сайтов веб раскрутка сайта дешево

Планируете каникулы? купить https://camp-centr.com! Интересные программы, безопасность, забота и яркие эмоции. Бронируйте заранее — количество мест ограничено!

Collectors often appreciate how each silicon baby is unique. From skin tone to hair texture, no two dolls look exactly alike. This individuality makes them special treasures for those who love reborn artistry.

Collectors often appreciate how each silicon baby is unique. From skin tone to hair texture, no two dolls look exactly alike. This individuality makes them special treasures for those who love reborn artistry.

riobet официальный riobet онлайн

stacking steroids tips https://anabolshop.org/

купить анализ антитела analiz-kupit-spb.ru

Топ сайтов кейсов CS2 ggdrop.cs2-case org проверенные сервисы с высоким шансом дропа, промокодами и моментальными выводами. Только актуальные и безопасные платформы!

Лучшие сайты кейсов http://www.ggdrop.casecs2.com в CS2 – честный дроп, редкие скины и гарантии прозрачности. Сравниваем платформы, бонусы и шансы. Заходи и забирай топовые скины!

1Block Casino: Full Platform Overview

1Block Casino is a modern gaming platform that offers a wide range of gambling entertainment for players worldwide. From classic slots to unique games like Plinko, the service provides everything needed for gambling enthusiasts. Let’s take a closer look at the main features of the platform, game categories, and key advantages.

Game Categories

1Block Casino boasts an extensive collection of games divided into several categories:

Originals

This section features exclusive games developed specifically for the platform. It’s a great choice for those seeking a unique gaming experience.

Slots

Classic and modern slots with various themes, bonuses, and mechanics are available here. Whether you prefer traditional fruit machines or innovative video slots, there’s something for everyone.

Live Games

Immerse yourself in the atmosphere of a real casino with live dealer games. These games are streamed in real-time, offering an authentic experience with professional dealers.

Fishing Games

A unique category that combines gambling with interactive gameplay. Fishing games are gaining popularity due to their engaging mechanics and potential for big wins.

Poker

Test your skills against other players in various poker formats. The platform offers both traditional and fast-paced poker games.

Esports Betting

Bet on your favorite esports teams and tournaments. This section caters to fans of competitive gaming who want to add excitement to their matches.

Lucky Bets and High Rollers

1Block Casino caters to all types of players, from casual gamers to high rollers. The Lucky Bets section highlights random wins, while the High Rollers section showcases impressive payouts from large bets. Whether you’re betting small or large amounts, the platform ensures fair play and exciting opportunities.

Our Community and Partnerships

1Block Casino values its community and collaborates with trusted partners to enhance the gaming experience. The platform proudly works with leading providers, ensuring top-quality games and services for its users.

Legal Information

1Block Casino is owned and operated by JogoMaster Limited, a company registered under number 15748. The company’s registered address is located in Hamchako, Mutsamudu, Autonomous Island of Anjouan, Union of Comoros.

The platform is licensed and regulated by the Gaming Board of Anjouan (License No. ALSI-152406032-FI3). 1Block has passed all regulatory compliance checks and is legally authorized to conduct gaming operations for all games of chance and wagering.

Why Choose 1Block Casino?

Diverse Game Selection : From slots to live games, there’s something for every type of player.

Transparency : All bets and payouts are clearly displayed, ensuring trust and fairness.

Crypto-Friendly : The platform supports cryptocurrency transactions, making it convenient for modern players.

Licensed and Regulated : With a valid license from the Gaming Board of Anjouan, players can enjoy a secure and legal gaming experience.

Whether you’re a fan of classic casino games or looking to explore unique options like Plinko, 1Block Casino offers a comprehensive and enjoyable platform for all gambling enthusiasts.

The appeal of silicon baby dolls lies in their attention to detail. From the finely painted features to the carefully sculpted limbs, each doll tells its own story. Many collectors appreciate these dolls not just for aesthetics but also as companions or therapeutic tools.

The appeal of silicon baby dolls lies in their attention to detail. From the finely painted features to the carefully sculpted limbs, each doll tells its own story. Many collectors appreciate these dolls not just for aesthetics but also as companions or therapeutic tools.

кайт школа анапа

ремонт холодильников dexp ремонт стиральных машин

Кладбище в Видном http://vidnovskoe.ru актуальные данные о захоронениях, помощь в организации похорон, услуги по благоустройству могил. Схема проезда, часы работы и контактная информация.

https://plomba77.ru/plombi-dlja-plombiratora/plombi-trubchatie-aluminievye В мире защиты и контроля доступа, одноразовые пластиковые пломбы роторного типа занимают особое место. Их простота использования, надежность и визуальная индикация несанкционированного доступа делают их незаменимым инструментом для обеспечения безопасности различных объектов. Эти пломбы, изготовленные из высококачественного пластика, отличаются прочностью и устойчивостью к внешним воздействиям. Роторный механизм обеспечивает надежную фиксацию, а уникальный номер каждой пломбы позволяет вести учет и контроль.

Аккредитованное агентство https://pravo-migranta.ru/ по аутстаффингу мигрантов и миграционному аутсорсингу. Оформление иностранных сотрудников без рисков. Бесплатная консультация и подбор решений под ваш бизнес.

Swiat emocji z 1win https://1win-pl.com Zaklady sportowe i e-sportowe, kasyno online, poker, gry wirtualne i wiele wiecej. Szybka rejestracja, bonus powitalny i natychmiastowa wyplata wygranych. 1win – wszystko, czego potrzebujesz do gry w jednym miejscu!

Официальный сайт 1win http://www.1win.kykyryza.ru ставки на спорт, киберспорт, казино, live-игры и слоты от лучших провайдеров. Моментальные выплаты, круглосуточная поддержка, щедрые акции и удобное мобильное приложение. Делай ставки и играй в казино на 1win — быстро, безопасно и выгодно!

Find the Perfect Clock clocks top for Any Space! Looking for high-quality clocks? At Top Clocks, we offer a wide selection, from alarm clocks to wall clocks, mantel clocks, and more. Whether you prefer modern, vintage, or smart clocks, we have the best options to enhance your home. Explore our collection and find the perfect timepiece today!

Dieser Blogbeitrag auf Hallofussball-Shop beschreibt das exklusive Real Madrid Y3 Trikot, das extra für Fans entworfen wurde. Es betont das außergewöhnliche Design und die erstklassige Verarbeitung hervor, die aus recyceltem Material besteht. Das Trikot ist Teil einer limitierten Edition für die Saison 2024 und bietet Fans die Möglichkeit, ein Stück ihrer Lieblingsmannschaft zu besitzen. Die Mischung aus modernem Stil und traditionellem Vereinsgeist macht es zu einem begehrten Artikel für alle Real Madrid-Fane.

кайт

онлайн казино Мир казино всегда манил яркими огнями, звоном монет и обещанием легкой удачи. От помпезных залов Лас-Вегаса до уютных уголков Монте-Карло, казино – это не только игра, но и целая индустрия, живущая по своим правилам. С развитием технологий казино перешли в онлайн-пространство. Онлайн-казино – это виртуальные платформы, предлагающие широкий спектр азартных игр, от классических слотов до карточных игр с живыми дилерами. Удобство, доступность и разнообразие делают онлайн-казино все более популярными.

работа за границей телеграм

Добро пожаловать в 1win https://1win.onedivision.ru азарт, спорт и выигрыши рядом! Ставь на матчи, играй в казино, участвуй в турнирах и получай крутые бонусы. Удобный интерфейс, быстрая регистрация и выплаты.

Бесплатные Steam аккаунты https://t.me/GGZoneSteam с играми и бонусами. Проверенные логины и пароли, ежедневное обновление, удобный поиск. Забирай свой шанс на крутой аккаунт без лишних действий!

кайтсёрфинг в хургаде

Доска объявлений https://estul.ru/blog по всей России: продавай и покупай товары, заказывай и предлагай услуги. Быстрое размещение, удобный поиск, реальные предложения. Каждый после регистрации получает на баланс аккаунта 100? для возможности бесплатного размещения ваших объявлений

кайт школа анапа

Valuable information. Lucky me I found your website by accident, and I’m shocked why this accident did not happened earlier! I bookmarked it.

Maispin——2025年最新USDT娛樂城,安全、快速、刺激!

歡迎來到 Maispin,2025年最具潛力的新秀 USDT娛樂城!在這裡,您只需提供 錢包地址 即可註冊,無需繁瑣的個人資訊,享受 安全、匿名、快速 的遊戲體驗。Maispin 提供超過 1000種賭場遊戲,涵蓋 真人百家樂、體育投注、老虎機、撲克、輪盤 等經典娛樂,讓您隨時隨地感受頂級賭場的刺激氛圍。我們與世界知名遊戲供應商合作,確保遊戲 公平公正,並提供高額彩金、獎勵活動,讓玩家輕鬆贏大獎!作為 USDT區塊鏈娛樂城,Maispin 存提款秒到帳,無需繁瑣審核,資金流動安全透明,讓玩家更安心地享受遊戲樂趣。立即加入 M宇宙,體驗前所未有的加密娛樂新潮流!

Самые новые анекдоты anekdotovmir.ru — коротко, метко и смешно! Подборка актуального юмора: от жизненных до политических. Заходи за порцией хорошего настроения!

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

Кладбища Видного https://bulatnikovskoe.ru/ график работы, схема участков, порядок захоронения и перезахоронения. Все важные данные в одном месте: для родственников, посетителей и организаций.

Представьте: шубе из соболя 50 лет, она пережила эпохи, видела балы, тайные встречи, рассветы над дворцами. Но её реинкарнировали(перешили)! Роскошь, ставшая тенью самой себя… Как можно было так поступить? Вы бы осмелились изменить историю, стереть отпечатки времени? Смотрите.. https://t.me/ElenaMeel/32

I really like your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz reply as I’m looking to design my own blog and would like to know where u got this from. appreciate it

F*ckin¦ tremendous things here. I¦m very glad to look your article. Thank you so much and i’m having a look forward to touch you. Will you kindly drop me a mail?

безопасная сделка аккаунтов продать аккаунт

кайтсерфинг в египте

USDT娛樂城

Maispin——2025年最新USDT娛樂城,安全、快速、刺激!

歡迎來到 Maispin,2025年最具潛力的新秀 USDT娛樂城!在這裡,您只需提供 錢包地址 即可註冊,無需繁瑣的個人資訊,享受 安全、匿名、快速 的遊戲體驗。Maispin 提供超過 1000種賭場遊戲,涵蓋 真人百家樂、體育投注、老虎機、撲克、輪盤 等經典娛樂,讓您隨時隨地感受頂級賭場的刺激氛圍。我們與世界知名遊戲供應商合作,確保遊戲 公平公正,並提供高額彩金、獎勵活動,讓玩家輕鬆贏大獎!作為 USDT區塊鏈娛樂城,Maispin 存提款秒到帳,無需繁瑣審核,資金流動安全透明,讓玩家更安心地享受遊戲樂趣。立即加入 M宇宙,體驗前所未有的加密娛樂新潮流!

аккаунты с балансом https://birzha-accauntov.ru

безопасная сделка аккаунтов magazin-accauntov.ru/

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:сервисные центры в москве

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

аккаунты с балансом https://ploshadka-dlya-prodazhi-akkauntov.ru/

I’ve been surfing online more than three hours these days, but I never found any fascinating article like yours. It is pretty worth sufficient for me. In my opinion, if all web owners and bloggers made good content as you did, the net might be much more useful than ever before.

Такси из аэропорта Белград Служба Такси Эклипс предлагает доступные трансферы из аэропортов Бургас, Варна, София и Белград до популярных курортов Болгарии. Встреча с табличкой, помощь с багажом и комфортная поездка до места назначения. Обслуживаем Солнечный Берег, Созополь, Банско и другие направления. Для групп от 5 человек – специальные условия!

магазин аккаунтов https://kupit-accaunt.ru

заработок на аккаунтах prodat-akkaunt.ru/

Thanks so much for giving everyone such a remarkable chance to read from this web site. It is always so pleasurable and jam-packed with a lot of fun for me and my office co-workers to visit your site no less than 3 times in one week to find out the latest guides you will have. Of course, I am always happy with your powerful tips and hints you give. Certain 4 ideas in this posting are without a doubt the very best we have had.

услуги по продаже аккаунтов биржа аккаунтов

Мечтаете о роскошном авто, сочетающем в себе передовые технологии и безупречный дизайн? Дубай – это сокровищница автомобильных шедевров, где представлены модели, способные удовлетворить самый взыскательный вкус. Компания ChatMost предлагает полный спектр услуг по заказу и доставке автомобилей из Дубая в Россию, избавляя вас от хлопот и рисков. Мечтаете о машине из Дубая

Напыление бровей Уже 10 лет Делаем качественный перманентный макияж в Анапе без синих красных бровей. Только премиум материалы , стерильно и без боли, работаем в любых техниках.

Обучаем перманентному макияжу с нуля со свидетельством установленного образца , ведем курсы бровистов

хостинг для создания сайта vps хостинг украина

VANGPOKER- новое идеальное место для покера!

Ведущая в мире платформа блокчейн покера!

Вы можете стать одними из первых участников нового проекта с честным рейкбэком, бонусом на первый депозит 200%, быстрым вводом и выводом, и отсутствием KYC.

Приглашаем вас присоединится к крупнейшему сообществу VANGPOKER в телеграмм, зарегестрироваться в VANGPOKER и получать дополнительные бонусы и повышенный рейкбэк. зарегестрироваться в VANGPOKER

кайт анапа

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to more added agreeable from you! By the way, how can we communicate?

роллы недорого суши роллы доставка

дайвинг в египте хургада

дайвинг в хургаде цены

Горкинское кладбище https://gorkinskoe.ru одно из старейших в Видном. Подробная информация: адрес, как доехать, порядок захоронений, наличие участков, памятники, услуги по уходу.

кайтсерфинг хургада Окунитесь в незабываемое приключение с кайт сафари в Хургаде. Исследуйте лучшие кайт споты, насладитесь кристально чистой водой и нетронутой природой.

Всё о Казахстане https://tr-kazakhstan.kz/ история, культура, города, традиции, природа и достопримечательности. Полезная информация для туристов, жителей и тех, кто хочет узнать страну ближе.

Kvalitni nabytek v Praze https://www.ruma.cz stylove reseni pro domacnost i kancelar. Satni skrine, sedaci soupravy, kuchyne, postele od proverenych vyrobcu. Rozvoz po meste a montaz na klic.

кайт блага

Офіційний сайт 1win visitkyiv com ua спортивні ставки, онлайн-казино, покер, live-ігри, швидкі висновки. Бонуси новим гравцям, мобільний додаток, цілодобова підтримка.

https://kiteschoolhurghada.ru

Доска бесплатных объявлений http://salexy.kz Казахстана: авто, недвижимость, техника, услуги, работа и многое другое. Тысячи свежих объявлений каждый день — легко найти и разместить!

ремонт квартир Пушкино Москва – динамичный мегаполис, где каждый стремится к созданию уютного и функционального пространства. Ремонт квартир в Москве – это не просто обновление интерьера, это инвестиция в комфорт и качество жизни. Мы предлагаем полный спектр услуг по ремонту квартир в Москве, от косметического обновления до капитальной перепланировки под ключ.

Всё о кладбищах Видного bitcevskoe Битцевское, Дрожжинское, Спасское, Жабкинское. Официальная информация, участки, услуги, порядок оформления документов, схема проезда.

Calibry Casino https://calibri-casino-app.ru современное онлайн-казино с лицензией, щедрой бонусной системой и широким выбором игр. Участвуй в акциях, получай кэшбэк и выигрывай реальные деньги!

The next time I read a blog, I hope that it doesnt disappoint me as much as this one. I mean, I know it was my choice to read, but I actually thought youd have something interesting to say. All I hear is a bunch of whining about something that you could fix if you werent too busy looking for attention.

гарантия при продаже аккаунтов безопасная сделка аккаунтов

гарантия при продаже аккаунтов https://prodaja-akkauntov.ru/

купить аккаунт с прокачкой https://marketpleysakkauntov.ru

Имморталы CS2 https://cs-open-case.ru/ редкие скины, которые выделят тебя в матче. Торгуй, покупай, продавай топовые предметы с моментальной доставкой в инвентарь. Лучшие цены и безопасные сделки!