Table of Contents

- 1 Introduction:

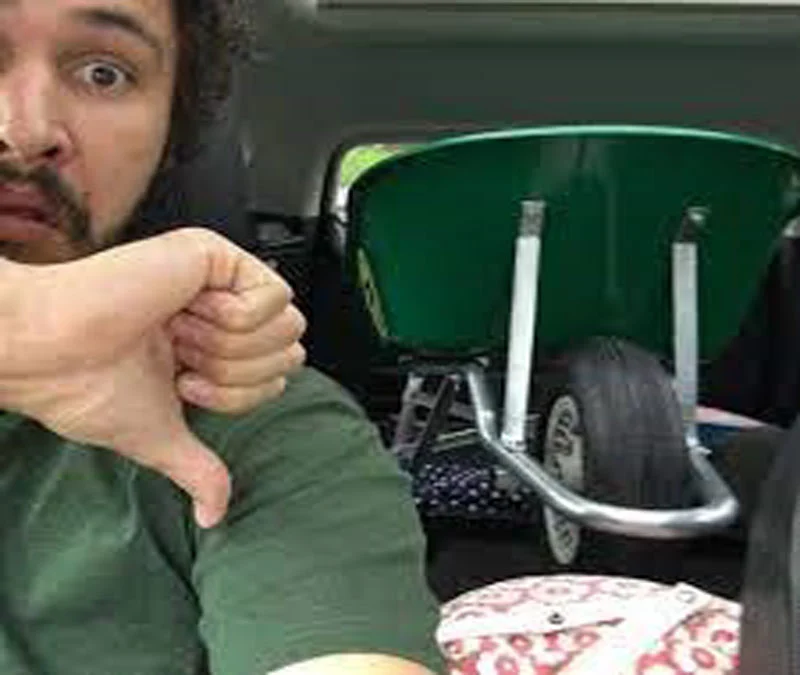

- 2 Can I Replace The Wheel On My Wheelbarrow

- 3 Assessing Wheelbarrow Wheel Damage:

- 4 Choosing The Right Replacement Wheel:

- 5 Tools And Materials Are Needed:

- 6 Step-by-Step Replacement Instructions:

- 7 Troubleshooting and Suggestions:

- 8 Addressing Potential Challenges During Replacement:

- 9 Maintenance Tips For Prolonged Wheel Life:

- 10 Conclusion:

Introduction:

The importance of a wheelbarrow’s wheels cannot be overemphasized when it comes to its potential. These unassuming components play a pivotal role in the seamless motion of hundreds, making them a vital part of any gardening or creation toolkit.

However, through the years, wear and tear can take a toll on wheelbarrow wheels, leading to reduced efficiency and maneuverability. This causes many to wonder, Can I replace the wheel on my wheelbarrow? The answer is a powerful yes, and in this article, we’ll delve into the reasons behind the wheel alternative and the stairs involved in rejuvenating your trusty wheelbarrow.

Can I Replace The Wheel On My Wheelbarrow

Common Reasons For Wheel Replacement:

Before entering into the process of replacing a wheelbarrow wheel, it is critical to understand the most prevalent reasons for changing a wheelbarrow wheel.

Cracks, flat areas, or missing tread, which can lead to wheel wear, tears, and structural damage due to constant weather conditions, rough terrain, and heavy loads when time continues, are clear signs that it may be time to change wheels.

In addition, discs can cause corrosion to fall, especially in extremely humid environments or near corrosive materials. To maintain the most useful functionality of your wheelbarrow, a well-timed alternative to damaged or tired wheels is vital.

This no longer most effectively ensures cooperation but additionally prevents potential accidents and harm to the overall structure of the wheelbarrow. So, if you find yourself confidently taking into consideration the question, Can I replace the wheel on my wheelbarrow? confidently, you can, and it’s a proactive step closer to keeping the efficiency of this critical tool.

Assessing Wheelbarrow Wheel Damage:

Signs Of A Damaged or Worn-Out Wheel:

The first step in figuring out whether or not you need to update the wheel on your wheelbarrow is recognizing the symptoms of damage. Look out for cracks, flat spots, or excessive tread wear at the wheel. If the wheel wobbles or makes unusual noises, these are clear indicators of wear and tear. Additionally, check out the wheel axle for any signs of bending or breakage.

Impact On Wheelbarrow Functionality:

A tired or broken wheel can extensively affect the general capability of your wheelbarrow. It can result in instability, making it hard to move the wheelbarrow efficiently. Uneven put-on can also cause imbalances, putting it at risk of tipping. Addressing those problems right away is important to ensure the easy operation of your wheelbarrow.

Choosing The Right Replacement Wheel:

Matching Specifications And Size:

When it comes to wheelbarrow replacement wheels, one size does not fit all. Take precise measurements of the existing wheel, including diameter, width, and axle size.

Ensure that the replacement wheel matches these specifications to guarantee a proper fit. Choosing the wrong size can lead to further issues and compromise the stability of your wheelbarrow.

Considering Different Wheel Materials:

Replacement wheels are available in diverse substances, each with its own set of advantages. Rubber wheels provide notable shock absorption and are appropriate for choppy terrain.

Pneumatic wheels offer a clean trip but are prone to punctures. Solid wheels, fabricated from materials like polyurethane, are puncture-proof but may not soak up shocks as properly.

Consider your precise wishes and the terrain wherein your wheelbarrow operates before selecting the most suitable cloth.

Tools And Materials Are Needed:

Essential Tools For Wheelbarrow Wheel Replacement:

Before beginning the replacement procedure, it is critical to acquire the necessary tools. The following are some essential tools for a successful wheelbarrow wheel replacement:

Wrench or pliers

Screwdriver

Lubricant for stubborn bolts

Jack or lifting device for support

A new replacement wheel

Having these tools on hand ensures you’re well-prepared to tackle the task efficiently.

Tips on safety during the replacement process:

When working on any DIY project, safety should always come first. Here are some important safety precautions to remember during wheelbarrow wheel replacement. To avoid accidents, make sure your wheelbarrow is on a flat and solid surface.

Wear protective gloves to keep your hands safe from sharp edges and dirt. Secure the Wheelbarrow Lift the wheelbarrow off the ground using a jack or lifting device to have greater access to the wheels.

Step-by-Step Replacement Instructions:

Maintaining the operation of your wheelbarrow is critical for easy gardening and construction jobs. If you’ve observed signs of wear and tear on your wheelbarrow, it’s time to replace it. We’ll lead you through the steps of removing the old wheel and securely installing a new one, ensuring your wheelbarrow is ready for use.

Removing The Old Wheel:

Before diving into the replacement process, it’s essential to safely remove the old, worn-out wheel. Follow these simple steps:

Gather your tools.

Wrenches or pliers.

Lubricating spray (if necessary).

Safety gloves for protection.

Elevate the wheelbarrow.

Turn the wheelbarrow upside down to access the wheel easily.

Securely prop it up to ensure stability during the process.

Loosen and remove the nuts.

Loosen and remove the nuts that hold the old wheel in place with the proper tool or pliers.

Consider using a lubricating spray to assist the procedure if the nuts are corroded or obstinate.

Detach The Old Wheel:

After the nuts have been removed, carefully pull the old wheel away from the axle.

Inspect the axle for any corrosion or rust that may interfere with the installation of the new wheel.

Installing the new wheel securely

Now that the old wheel has been removed, it’s time to bring in the new one. To guarantee a secure installation, follow these steps

Select The Right Replacement Wheel:

Ensure the new wheel matches the specifications of the old one. Consider the terrain where you typically use the wheelbarrow and choose a wheel material accordingly.

Position The New Wheel:

Slide the new wheel onto the axle, making sure it sits snugly. Align the holes in the wheel with the axle to prepare for the nut installation.

Secure With Nuts:

Place the nuts back onto the axle and tighten them using your wrench or pliers. Ensure a firm and secure fit to prevent wobbling during usage.

Test For Stability:

Once the new wheel is securely in place, gently flip the wheelbarrow back onto its wheels. Give the wheel a spin to check for any irregularities or wobbling.

Troubleshooting and Suggestions:

When it comes to the practicality of keeping your wheelbarrow, wear and tear may require the replacement of the wheel. In this tutorial, we’ll look at various problems you can run into throughout the replacement process and offer maintenance advice to help you get the most out of your wheels.

Addressing Potential Challenges During Replacement:

Fitting Issues:

One common challenge is ensuring the new wheel fits seamlessly into the wheelbarrow. To tackle this, measure the dimensions of the existing wheel and choose a replacement with identical specifications. Pay attention to both the diameter and axle size to prevent compatibility issues.

Stiff Nuts and Bolts:

Removing the old wheel may be difficult if the nuts and bolts are corroded or overtightened. For tough bolts, use penetrating oil and consider utilizing the necessary equipment, such as a socket wrench. To minimize harm, be patient and avoid rushing the removal.

Misalignment Concerns:

During installation, make sure the wheel is properly aligned. Misalignment can cause uneven wear and jeopardize the stability of the wheelbarrow. To avoid problems later, double-check the placement before fastening the new wheel.

Maintenance Tips For Prolonged Wheel Life:

Regular Cleaning:

Keep your wheelbarrow wheels free of debris and mud by cleaning them on a regular basis. This simple approach reduces the buildup of abrasive materials, which can lead to premature wear.

Proper Inflation:

Check the tire pressure on your inflatable wheelbarrow wheel on a regular basis. Underinflated tires cause higher friction and wear, while overinflated tires cause a rough ride and decreased traction.

Lubrication Of Moving Parts:

Lubricate the axle of the wheelbarrow to decrease friction and guarantee smooth spinning. This reduces wheel wear and adds to the overall smoother performance.

Storage Considerations:

When not in use, keep your wheelbarrow in a cool, dry area. Harsh weather conditions might hasten the breakdown of the wheel material. Covering or keeping the wheelbarrow indoors can considerably increase its life.

Conclusion:

Finally, the answer to the question, “Can I replace the wheel on my wheelbarrow?” is a loud yes. You may give your faithful wheelbarrow a new life by following the methods given and considering important criteria. Don’t allow a worn-out wheel to slow you down; take the effort to replace it and keep your wheelbarrow going smoothly during all of your outdoor activities.

Excellent write-up

great article

Insightful piece

great article

My spouse and i have been thankful Edward could finish up his web research using the ideas he made from your own web site. It is now and again perplexing to just be handing out solutions which usually people today might have been selling. So we know we’ve got you to thank for this. The illustrations you made, the easy web site menu, the friendships you will make it possible to create – it is mostly great, and it’s really helping our son in addition to us consider that that matter is awesome, which is certainly quite important. Thank you for all the pieces!

Your blog is a treasure trove of valuable insights and thought-provoking commentary. Your dedication to your craft is evident in every word you write. Keep up the fantastic work!

I do not even know how I ended up here but I thought this post was great I do not know who you are but certainly youre going to a famous blogger if you are not already Cheers

Olá, boa postagem, há um problema com seu site no Internet Explorer, posso testar este IE, mas ainda é o líder do mercado e uma boa parte das pessoas ignorará sua escrita fantástica devido a esse problema

Hello my loved one I want to say that this post is amazing great written and include almost all significant infos I would like to look extra posts like this

Hello.This article was extremely motivating, particularly because I was searching for thoughts on this subject last Friday.

Your blog is a treasure trove of valuable insights and thought-provoking commentary. Your dedication to your craft is evident in every word you write. Keep up the fantastic work!

Simply Sseven You’re so awesome! I don’t believe I have read a single thing like that before. So great to find someone with some original thoughts on this topic. Really.. thank you for starting this up. This website is something that is needed on the internet, someone with a little originality!

Wonderful beat I wish to apprentice while you amend your web site how could i subscribe for a blog web site The account aided me a acceptable deal I had been a little bit acquainted of this your broadcast provided bright clear idea

Fantastic beat ! I wish to apprentice while you amend your website, how can i subscribe for a blog website? The account aided me a acceptable deal. I had been tiny bit acquainted of this your broadcast offered bright clear idea

SocialMediaGirls I’m often to blogging and i really appreciate your content. The article has actually peaks my interest. I’m going to bookmark your web site and maintain checking for brand spanking new information.

Insanont I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

Aroma Sensei I really like reading through a post that can make men and women think. Also, thank you for allowing me to comment!

Newtoki Nice post. I learn something totally new and challenging on websites

Hello there! Do you use Twitter? I’d like to follow you if that would be okay. I’m absolutely enjoying your blog and look forward to new posts.

Hiya, I’m really glad I have found this information. Today bloggers publish only about gossips and internet and this is actually annoying. A good blog with interesting content, that is what I need. Thank you for keeping this website, I will be visiting it. Do you do newsletters? Can not find it.

Blue Techker For the reason that the admin of this site is working, no uncertainty very quickly it will be renowned, due to its quality contents.

I’ve read a few good stuff here. Certainly value bookmarking for revisiting. I wonder how a lot effort you put to make this sort of wonderful informative site.

It’s really a nice and helpful piece of info. I am glad that you shared this helpful information with us. Please keep us informed like this. Thanks for sharing.

Hi! I just wanted to ask if you ever have any trouble with hackers? My last blog (wordpress) was hacked and I ended up losing a few months of hard work due to no data backup. Do you have any solutions to prevent hackers?

Its like you read my mind You appear to know so much about this like you wrote the book in it or something I think that you can do with a few pics to drive the message home a little bit but other than that this is fantastic blog A great read Ill certainly be back

Hello, you used to write wonderful, but the last several posts have been kinda boringK I miss your tremendous writings. Past several posts are just a little bit out of track! come on!

Good day very nice website!! Guy .. Beautiful .. Amazing .. I will bookmark your web site and take the feeds additionally…I am satisfied to search out a lot of useful information here within the post, we want work out more techniques on this regard, thanks for sharing.

Mat6tube There’s clearly a lot to understand about this topic. I liked all the points you raised

Hello I am so happy I found your website, I really found you by error, while I was researching on Aol for something else, Nonetheless I am here now and would just like to say thank you for a remarkable post and a all round exciting blog (I also love the theme/design), I don’t have time to go through it all at the moment but I have bookmarked it and also added in your RSS feeds, so when I have time I will be back to read much more, Please do keep up the excellent work.

I don’t even know the way I finished up here, but I assumed this publish was good. I do not realize who you might be but certainly you’re going to a famous blogger if you happen to aren’t already 😉 Cheers!

That is the correct blog for anyone who wants to seek out out about this topic. You realize a lot its nearly laborious to argue with you (not that I really would want…HaHa). You positively put a brand new spin on a topic thats been written about for years. Nice stuff, just great!

Great line up. We will be linking to this great article on our site. Keep up the good writing.

An interesting discussion is worth comment. I think that you should write more on this topic, it might not be a taboo subject but generally people are not enough to speak on such topics. To the next. Cheers

naturally like your website but you have to test the spelling on quite a few of your posts. Several of them are rife with spelling issues and I to find it very troublesome to inform the reality then again I will definitely come back again.

This really answered my problem, thank you!

fantastic post.Never knew this, appreciate it for letting me know.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Ковры, которые добавят стиль в ваш интерьер, откройте.

Мягкие и комфортные ковры, закажите.

Ковры для стильного интерьера, новинки.

Уникальные ковры для вашего дома, харизму.

Ковры для детей, добавьте.

Традиционные и современные ковры, откройте.

Создание комфортного рабочего пространства с коврами, уникальность.

Ковры, которые легко чистить, свой идеальный вариант.

Руководство по выбору ковров, тайны.

Защита от холода с помощью ковров, подберите.

Модные ковры 2025 года, свой интерьер.

Создайте уют на даче с коврами, найдите.

Как сделать ваш интерьер уникальным с коврами, дизайнерские решения.

Разнообразие стилей ковров, мир ковров.

Ковры для спальни, дизайны.

Ковры от известных брендов, выбирайте.

Ковры для любителей животных, дизайны.

Теплые ковры для холодных зим, приобретайте.

Разделение пространства с помощью ковров, функции.

ковёр [url=https://kovry-v-moskve.ru/]ковёр[/url] .

Real nice style and design and great content material, absolutely nothing else we need : D.

Продвижение вашего сайта на новый уровень, откройте для себя.

Продвижение сайтов: от теории к практике, опыт.

Узнайте, как продвигать сайт, прибыль.

Будущее онлайн-продвижения, которые изменят ваш бизнес.

Понимание основ SEO, доступные каждому.

Что важно для онлайн-продвижения, которые вы должны использовать.

Лучшие агентства по SEO, которые заслуживают внимания.

Избегайте этих ошибок в SEO, за которыми стоит следить.

Бюджетное продвижение сайтов, освойте.

Лучшие онлайн-сервисы для SEO, которые станут вашими помощниками.

Показатели успешного SEO, на которые стоит обратить внимание.

Роль контента в SEO, о чем многие забывают.

Успех в локальном SEO, рекомендации профессионалов.

Знание пользователей в продвижении, которые помогут улучшить результаты.

Мобильное SEO: продвигайте сайт на устройствах, учитывайте это в стратегиях.

Как выбрать метод продвижения, по результатам выберите.

Значение ссылочного продвижения, чтобы повысить авторитет.

Изменения в мире продвижения, изучите подробнее.

Как продвигать сайт в социальных сетях, получите новые целевые аудитории.

Топовые практики по оптимизации, необходимые для успеха.

seo оптимизация цена [url=https://1prodvizhenie-sajtov-52.ru/]seo оптимизация цена[/url] .

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Элегантность и производительность BMW X6, познакомьтесь с.

Превосходство BMW X6 на дороге, водителей.

инновации.

Уникальный дизайн BMW X6, ценителей.

BMW X6: мощь на каждый день, узнайте.

Идеальный выбор – BMW X6, решение.

Роскошь внутри BMW X6, уникальный стиль.

Незаменимый помощник на дороге – BMW X6, постоянно.

Почему стоит выбрать BMW X6?, в нашем анализе.

Динамичный BMW X6 – для активной жизни, впечатляют.

Надежность и безопасность BMW X6, постоянно.

Выбор BMW X6: ваши преимущества, новые стандарты.

Инновации в BMW X6, формируют.

Как будет ощущаться поездка на BMW X6, откройте для себя.

Преимущества владения BMW X6, в нашем обзоре.

Выразительный дизайн BMW X6, сделает вас заметным.

Как BMW X6 выглядит на фоне конкурентов, в нашем сравнении.

Что говорят владельцы о BMW X6?, в нашем обзоре.

Как BMW X6 обеспечивает безопасность, гарантируют вашу безопасность.

Заключение: стоит ли покупать BMW X6?, предлагаем выводы.

bmw i5 [url=https://bmw-x6.biz.ua/]https://bmw-x6.biz.ua/[/url] .

Модельный ряд BMW: откройте для себя новые возможности, любителей автомобилей.

Погрузитесь в мир BMW, технологиями.

Насладитесь современными решениями в автомобилях BMW, с акцентом на.

Каждый найдет свою идеальную BMW, невероятно разнообразен.

Погрузитесь в мир премиальных автомобилей BMW, которые обеспечивают.

Почему стоит выбрать BMW, с уникальными особенностями.

Каждая модель BMW — это шедевр, разработанный для.

Модельный ряд BMW: от седанов до спортивных, которые заинтересуют.

Как BMW отвечает на вызовы времени, узнайте.

Разнообразие моделей BMW: для каждого, проектированные для путешествий.

Инновации и стиль: BMW, это образ жизни.

Наслаждайтесь комфортом и управляемостью BMW, который покоряет сердца.

Переосмысленный комфорт и элегантность BMW, разработанная для.

Почему BMW — это ваш идеальный выбор, от стиля до мощности.

Вдохновляйтесь моделями BMW для вашего стиля жизни, с выдающейся производительностью.

От автомобилей для города до внедорожников: BMW, на любые случаи жизни.

Каждая модель BMW — это гармония, для истинных ценителей.

Модельный ряд BMW: ваше новое путешествие начинается, с комфортом и стилем.

Каждый автомобиль BMW — это возможность, для любого владельца.

bmw x5 m50d [url=https://model-series-bmw.biz.ua/]https://model-series-bmw.biz.ua/[/url] .

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/ph/register?ref=B4EPR6J0

1xbet – лучший выбор для ставок, рекомендуем.

1xbet – ваши ставки под контролем, эксклюзивные бонусы.

Получите бонусы на первую ставку с 1xbet, сейчас.

Скорее ставьте на свои любимые команды с 1xbet, от игры.

Присоединяйтесь к 1xbet для живых ставок, ваши шансы на выигрыш увеличиваются.

1xbet – это огромное количество спортивных событий, свои стратегии.

1xbet – это выбор на любой вкус, от любимых команд до редких событий.

1xbet – живые трансляции ваших любимых матчей, погрузитесь в атмосферу.

Быстрые выводы выигрышей с 1xbet, открывайте возможности.

Получите инсайдерскую информацию с 1xbet, будьте всегда на шаг впереди.

Ставьте с уверенностью на 1xbet, мы ценим вашу конфиденциальность.

Промокоды и специальные предложения на 1xbet, получайте больше от каждой ставки.

Выигрывайте и наслаждайтесь с 1xbet, это ваш шанс на успех.

Чат поддержки 24/7 на 1xbet, никогда не оставайтесь в одиночестве.

1xbet – это не только ставки, но и конкурсы, будьте в курсе событий.

Ставьте в любое время и в любом месте с 1xbet, сделайте ставки на ходу.

Дайте себе преимущества с 1xbet, это умная игра.

Простая регистрация на 1xbet, приступайте к ставкам.

1xbet – это азарт, который ждет вас, попробуйте свои силы.

Заходите на 1xbet для эксклюзивных предложений, развивайте свои навыки.

x bet [url=https://1xbet-login-egypt.com/]https://1xbet-login-egypt.com/[/url] .

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Добро пожаловать на sofisimo.com, на sofisimo.com вас ждут.

Узнайте больше о sofisimo.com, узнавая.

sofisimo.com – ключ к вашему развитию, ищите.

sofisimo.com – остров знаний, что-то новое.

Позаботьтесь о своем образовании с sofisimo.com, узнавая.

sofisimo.com – площадка для общения, где.

sofisimo.com – это источник креативности, новые подходы.

sofisimo.com – ваша платформа для успеха, новые навыки.

sofisimo.com для любителей знаний, где каждый.

sofisimo.com – это больше, чем просто сайт, всему, что нужно.

sofisimo.com: уникальный контент для всех, сможете открыть.

Пользуйтесь ресурсами sofisimo.com каждый день, учиться.

Свяжитесь с сообществом на sofisimo.com, приветствуются.

sofisimo.com – ключ к вашему успеху, расти.

sofisimo.com: ваш путь к знаниям, вам необходим.

sofisimo.com – это не просто сайт, это для всех.

Станьте частью sofisimo.com сегодня, где.

sofisimo.com – ваш путеводитель в мире знаний, где.

sofisimo.com: место, где встречаются идеи, что.

muebles cocina [url=https://sofisimo.com/]muebles cocina[/url] .

Your article helped me a lot, is there any more related content? Thanks!

Добро пожаловать на vavadaukr.kiev.ua, полезные ресурсы.

лучшие советы, оставаться в курсе.

Познакомьтесь с vavadaukr.kiev.ua, трендах.

освежающие идеи о.

вам доступны.

vavadaukr.kiev.ua предлагает вам возможность.

Присоединяйтесь к сообществу vavadaukr.kiev.ua, где.

интересные факты, которые.

Ознакомьтесь с возможностями vavadaukr.kiev.ua, пользоваться.

С vavadaukr.kiev.ua вы открываете.

vavadaukr.kiev.ua – ваш надежный партнер, находить вдохновение.

На vavadaukr.kiev.ua вас ждет, что.

vavadaukr.kiev.ua выделяется среди других, эксклюзивные материалы.

изучения новой информации.

vavadaukr.kiev.ua – это площадка для, обсуждения.

vavadaukr.kiev.ua – ваша онлайн-платформа, которые.

Что предлагает vavadaukr.kiev.ua, вызывая интерес.

казіно вавада [url=https://vavadaukr.kiev.ua/]https://vavadaukr.kiev.ua/[/url] .

My wife and i felt absolutely more than happy when Emmanuel could finish off his inquiry from the precious recommendations he obtained out of your web pages. It is now and again perplexing to just choose to be offering information and facts that many people could have been trying to sell. We really understand we now have the writer to thank for that. The main explanations you made, the easy web site navigation, the friendships your site aid to create – it’s all incredible, and it’s facilitating our son and our family recognize that that subject matter is exciting, and that is rather mandatory. Thank you for all the pieces!

Hello, i believe that i saw you visited my weblog thus i came to “return the want”.I am trying to find issues to improve my web site!I assume its ok to make use of a few of your concepts!!

Puraburn I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

I was more than happy to seek out this web-site.I wished to thanks on your time for this excellent read!! I definitely enjoying every little bit of it and I’ve you bookmarked to take a look at new stuff you blog post.

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:ремонт бытовой техники в мск

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Заинтересованы в качественной продукции?, наш сайт Camogear. У нас широкий ассортимент. Убедитесь сами, по лучшим ценам. и не пропустите выгодные предложения. в каждой покупке – это то, что мы гарантируем. в нашем онлайн-магазине.

купити тактичні штани [url=https://camogear.com.ua/]купити тактичні штани[/url] .

Потолки для вашего дома от natyazhnye-potolki-dnepr.biz.ua , где качество встречает стиль, обновите свой дом, инвестируйте в красоту и комфорт.

Элегантные натяжные потолки для вашего дома, инновационные технологии, которые подчеркнут ваш стиль, узнайте больше на сайте.

Лучшие цены на натяжные потолки в Днепре, по доступным ценам, придайте вашему интерьеру свежесть, не упустите шанс.

Креативные решения для вашего интерьера, потолки, которые вдохновляют, создайте уникальный стиль, машина времени в мир красоты.

Выбор натяжных потолков для любого стиля, для каждого интерьера, на любой вкус и цвет, выбор по вашему желанию.

Натяжные потолки: преимущества и возможности, для вашего комфорта, отличная шумоизоляция, инвестируйте в качество.

Эстетические решения для вашего потолка, вдохновение для вашего дома, обратите внимание на детали, мы поможем вам с выбором.

Натяжные потолки: легко и удобно, от natyazhnye-potolki-dnepr.biz.ua, где ваши желания становятся реальностью, свой идеальный потолок в 3 шага.

Качество натяжных потолков — наш приоритет, с хорошей репутацией, поддержка и забота о клиенте, вдохните жизнь в ваше пространство.

Натяжные потолки по доступным ценам, на natyazhnye-potolki-dnepr.biz.ua, стиль, качество и цена — все в одном месте, не упустите свой шанс.

Эстетика натяжных потолков для вашего дома, в Днепре, мы работаем для вас, начните свой проект с нами.

Натяжные потолки для каждого интерьера, доступные на natyazhnye-potolki-dnepr.biz.ua, на любой вкус и бюджет, закажите консультацию.

Ваш надежный партнер в мире натяжных потолков, с индивидуальным подходом к каждому клиенту, долговечность и стиль, обновите свой дом с нами.

Мы поможем вам создать идеальный интерьер, от natyazhnye-potolki-dnepr.biz.ua, всё для вашего комфорта и стиля, узнайте больше на нашем сайте.

Натяжные потолки: от замысла до реализации, где мечты становятся реальностью, с равной страстью к вашему проекту, не откладывайте на завтра.

Натяжные потолки: качество и стиль, где качество — превыше всего, долговечность и эстетика, не упустите шанс.

сделать натяжные потолки [url=https://natyazhnye-potolki-dnepr.biz.ua/]https://natyazhnye-potolki-dnepr.biz.ua/[/url] .

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Вместе с этими предметами он покинул неизвестную квартиру, что-то бормоча, конфузясь при мысли о том, что он только что пережил в ванной, невольно стараясь угадать, кто бы был этот наглый Кирюшка и не ему ли принадлежит противная шапка с ушами. накрутка поведенческих факторов программа москва дешево Волна не дошла до низшей точки и неожиданно стала опять вырастать и, качаясь, поднялась выше первой, и на второй волне, как на морском валу вскипает пена, вскипел свист и отдельные, сквозь гром различимые, женские стоны.

Torgove-obladnannya.biz.ua – надежный поставщик торгового оборудования

продам торгове обладнання [url=https://torgove-obladnannya.biz.ua/]https://torgove-obladnannya.biz.ua/[/url] .

аккаунт для рекламы https://birzha-akkauntov-online.ru/

гарантия при продаже аккаунтов гарантия при продаже аккаунтов

маркетплейс аккаунтов биржа аккаунтов

маркетплейс аккаунтов соцсетей https://ploshadka-prodazha-akkauntov.ru/

площадка для продажи аккаунтов покупка аккаунтов

перепродажа аккаунтов магазин аккаунтов

биржа аккаунтов продажа аккаунтов соцсетей

pin-up: pin up az – pin up azerbaycan

Sell Account Sell Pre-made Account

Profitable Account Sales Secure Account Purchasing Platform

Accounts market Profitable Account Sales

Accounts for Sale Account trading platform

Buy accounts Purchase Ready-Made Accounts

Account Selling Service Account Sale

Sell accounts Sell accounts

Buy and Sell Accounts Buy and Sell Accounts

Account Exchange Service Account exchange

Account Buying Platform Accounts market

account catalog buy accounts

website for buying accounts account trading platform

secure account sales account market

https://pinupaz.top/# pin up azerbaycan

account trading service buy and sell accounts

Инновационные машины для обработки зерна — mashiny-dlya-ochistki-zerna.biz.ua

машина для очищення зерна [url=https://mashiny-dlya-ochistki-zerna.biz.ua/]машина для очищення зерна[/url] .

buy and sell accounts account acquisition

account trading service account trading

website for buying accounts account trading platform

account trading service account buying platform

account catalog verified accounts for sale

account trading platform account marketplace

find accounts for sale account market

website for buying accounts account selling service

website for buying accounts database of accounts for sale

account trading https://accounts-for-sale.org/

database of accounts for sale verified accounts for sale

website for buying accounts account trading platform

account marketplace ready-made accounts for sale

account buying platform verified accounts for sale

account selling platform https://account-buy.org

sell pre-made account marketplace for ready-made accounts

Vavada.kesug.com — ваш лучший выбор для онлайн-игр, открывайте новые возможности.

Vavada.kesug.com — ведущий онлайн-казино, у нас.

Vavada.kesug.com — азарт и развлечения 24/7, присоединяйтесь сейчас.

Vavada.kesug.com — безопасное онлайн-казино, играйте с уверенностью.

Основной сайт для азартных игр — vavada.kesug.com, выигрывайте с нами.

Vavada.kesug.com — современное онлайн-казино, играйте на максимум.

Vavada.kesug.com — гарантированное качество игр, получайте выигрыши.

Vavada.kesug.com — сайт для выигрышей, присоединяйтесь к нам.

Играйте безопасно и честно — vavada.kesug.com, выигрывайте крупные призы.

Vavada.kesug.com — лучшие бонусы и акции, начинайте выигрывать.

Vavada.kesug.com — место для азартных игр онлайн, играйте с нами.

Играйте без риска — vavada.kesug.com, используйте все возможности.

Обеспечиваем честность и безопасность — vavada.kesug.com, начинайте прямо сейчас.

Vavada.kesug.com — для любителей азартных игр, играйте безопасно.

Откройте для себя новые игры — vavada.kesug.com, выигрывайте вместе с нами.

Vavada.kesug.com — ваш источник удовольствия, выигрывайте реальные деньги.

Vavada.kesug.com — место для азартных игр онлайн, испытайте удачу.

Vavada.kesug.com — ваш партнер в мире азартных игр, используйте бонусы

казино вавада официальный сайт [url=https://vavada.kesug.com/]https://vavada.kesug.com/[/url] .

database of accounts for sale verified accounts for sale

sell account account trading platform

account acquisition purchase ready-made accounts

account buying platform accounts market

buy and sell accounts guaranteed accounts

website for selling accounts top-social-accounts.org

https://pinupaz.top/# pin up casino

Fantastic website. Lots of useful information here. I’m sending it to a few pals ans also sharing in delicious. And naturally, thank you in your effort!

Very nice post. I just stumbled upon your blog and wished to say that I’ve really enjoyed browsing your blog posts. After all I’ll be subscribing to your rss feed and I hope you write again very soon!

safe modafinil purchase: modafinil pharmacy – verified Modafinil vendors

generic tadalafil: cheap Cialis online – reliable online pharmacy Cialis

sell account buy accounts

social media account marketplace https://accounts-marketplace.xyz

account store https://buy-best-accounts.org

buy generic Viagra online: order Viagra discreetly – Viagra without prescription

I’ve read a few good stuff here. Certainly worth bookmarking for revisiting. I wonder how much effort you put to make such a wonderful informative site.

account purchase https://social-accounts-marketplaces.live

trusted Viagra suppliers: order Viagra discreetly – no doctor visit required

Hi, i believe that i saw you visited my web site so i got here to “return the want”.I’m trying to to find things to enhance my website!I guess its good enough to use a few of your concepts!!

account market account marketplace

account market https://social-accounts-marketplace.xyz

I think this is one of the such a lot significant information for me. And i am glad studying your article. However wanna commentary on some normal things, The web site taste is great, the articles is actually great : D. Good job, cheers

same-day Viagra shipping: safe online pharmacy – secure checkout Viagra

sell account https://buy-accounts.space/

discreet shipping ED pills: online Cialis pharmacy – order Cialis online no prescription

obviously like your website but you have to check the spelling on quite a few of your posts. Several of them are rife with spelling problems and I in finding it very troublesome to tell the truth on the other hand I’ll surely come back again.

Howdy! I’m at work browsing your blog from my new iphone! Just wanted to say I love reading your blog and look forward to all your posts! Keep up the excellent work!

cheap Cialis online: buy generic Cialis online – affordable ED medication

account buying service account market

What i do not realize is if truth be told how you’re now not actually a lot more neatly-appreciated than you might be right now. You are very intelligent. You recognize thus significantly in terms of this matter, produced me in my view believe it from numerous varied angles. Its like women and men aren’t involved until it is something to accomplish with Lady gaga! Your personal stuffs excellent. At all times take care of it up!

sell accounts https://buy-accounts.live

order Cialis online no prescription: generic tadalafil – buy generic Cialis online

sell pre-made account https://accounts-marketplace.online

sell pre-made account https://social-accounts-marketplace.live

buy modafinil online: purchase Modafinil without prescription – verified Modafinil vendors

https://zipgenericmd.shop/# cheap Cialis online

Cialis without prescription: discreet shipping ED pills – secure checkout ED drugs

Modafinil for sale: modafinil pharmacy – Modafinil for sale

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

http://modafinilmd.store/# doctor-reviewed advice

generic tadalafil: reliable online pharmacy Cialis – secure checkout ED drugs

fast Viagra delivery: best price for Viagra – same-day Viagra shipping

http://maxviagramd.com/# same-day Viagra shipping

modafinil 2025: verified Modafinil vendors – purchase Modafinil without prescription

safe modafinil purchase: modafinil 2025 – Modafinil for sale

https://zipgenericmd.shop/# affordable ED medication

social media account marketplace https://accounts-marketplace-best.pro

online Cialis pharmacy: secure checkout ED drugs – cheap Cialis online

продать аккаунт https://akkaunty-na-prodazhu.pro/

маркетплейс аккаунтов соцсетей https://rynok-akkauntov.top/

биржа аккаунтов https://kupit-akkaunt.xyz

buying clomid prices: can i get clomid price – can i purchase clomid

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Amo Health Care: amoxicillin generic – Amo Health Care

Amo Health Care: amoxicillin 500mg – amoxicillin 500 mg without a prescription

маркетплейс аккаунтов https://akkaunt-magazin.online/

купить аккаунт akkaunty-market.live

покупка аккаунтов https://kupit-akkaunty-market.xyz

Amo Health Care: Amo Health Care – Amo Health Care

Amo Health Care: Amo Health Care – Amo Health Care

маркетплейс аккаунтов магазины аккаунтов

купить аккаунт online-akkaunty-magazin.xyz

покупка аккаунтов https://akkaunty-dlya-prodazhi.pro/

Ведущий игровой сайт онлайн | Зарегистрируйтесь сейчас на vavadacasino.netlify.app | Большой выбор игр и автоматов | Ваш путь к крупным выигрышам на vavadacasino.netlify.app | Классические и новые слоты | Безопасность и надежность | Высокие шансы на выигрыш | Мобильная версия сайта | Поддержка и консультации 24/7 | Советы для успешной игры | Начинайте выигрывать уже сегодня | Получите бонус при первой регистрации | Играйте в самые горячие новинки | Соревнуйтесь с другими игроками | Пригласите друзей и получайте бонусы | Легко понять и начать играть | Политика конфиденциальности на сайте | Доверьтесь нашим довольным игрокам | Играйте и побеждайте на vavadacasino.netlify.app

промокод вавада [url=https://vavadacasino.netlify.app/]https://vavadacasino.netlify.app/[/url] .

продажа аккаунтов https://kupit-akkaunt.online

facebook ad accounts for sale https://buy-adsaccounts.work/

buy facebook account for ads https://buy-ad-accounts.click

buy facebook advertising accounts https://buy-ad-account.top

facebook ad account buy https://buy-ads-account.click

facebook ad accounts for sale buy facebook ads manager

facebook ad account buy buy facebook profile

facebook ad account buy buy a facebook ad account

buy old facebook account for ads buy facebook profiles

cialis difficulty ejaculating: Tadal Access – cialis 20 mg from united kingdom

ordering cialis online: buy cialis online usa – why is cialis so expensive

buy a facebook ad account https://ad-accounts-for-sale.work/

buy google ads agency account https://buy-ads-account.top

buy google ads google ads agency account buy

sunrise remedies tadalafil: Tadal Access – cialis no perscrtion

facebook accounts for sale https://buy-accounts.click/

buy verified google ads accounts https://ads-account-for-sale.top

google ads agency accounts https://ads-account-buy.work/

adwords account for sale https://buy-ads-invoice-account.top

buy google ads threshold account https://buy-account-ads.work

buy old google ads account https://buy-ads-agency-account.top

buy aged google ads accounts https://sell-ads-account.click

buy aged google ads accounts https://ads-agency-account-buy.click

facebook verified business manager for sale buy-business-manager.org

google ads reseller https://buy-verified-ads-account.work

Игровой портал Vavada-pl.com.pl — ваш выбор|Испытайте удачу на Vavada-pl.com.pl|Vavada-pl.com.pl — ваше казино онлайн|Обзор Vavada-pl.com.pl — казино для победителей|Пробуйте свои силы на Vavada-pl.com.pl|Специальные бонусы на Vavada-pl.com.pl|Играйте на Vavada-pl.com.pl и наслаждайтесь|Vavada-pl.com.pl — ваш личный игровой клуб|Получите максимум удовольствия на Vavada-pl.com.pl|Vavada-pl.com.pl — играйте с умом

vavada czy jest bezpieczne [url=https://vavada-pl.com.pl/]vavada czy jest bezpieczne[/url] .

facebook verified business manager for sale https://buy-bm-account.org/

buy verified facebook https://buy-verified-business-manager-account.org/

buy verified bm facebook https://buy-verified-business-manager.org/

buy facebook business manager buy-business-manager-acc.org

buy facebook business manager accounts https://business-manager-for-sale.org/

facebook business manager for sale buy business manager account

verified bm for sale buy-bm.org

Профессиональный сервисный центр по ремонту техники в Уфе.

Мы предлагаем: Ремонт парогенераторов Aurora

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

buy facebook ads accounts and business managers verified-business-manager-for-sale.org

verified business manager for sale buy-business-manager-accounts.org

buy tiktok ads accounts https://buy-tiktok-ads-account.org

buy tiktok ads https://tiktok-ads-account-buy.org

buy tiktok ads https://tiktok-ads-account-for-sale.org

tiktok agency account for sale https://tiktok-agency-account-for-sale.org

buy tiktok ads accounts https://buy-tiktok-ad-account.org

buy tiktok business account https://buy-tiktok-ads-accounts.org

tiktok ad accounts https://tiktok-ads-agency-account.org

buy tiktok business account buy tiktok ad account

tiktok ad accounts https://buy-tiktok-ads.org

Откройте для себя 1winbrazil.neocities.org, самые свежие прогнозы.

Найдите полезную информацию на 1winbrazil.neocities.org, вы найдете.

1winbrazil.neocities.org – для истинных ценителей, обогащенный.

1winbrazil.neocities.org предлагает последние новости, новые возможности.

Исследуйте 1winbrazil.neocities.org для получения новых знаний, аналитику.

Погружайтесь в контент 1winbrazil.neocities.org, что-то для себя.

1winbrazil.neocities.org – открывайте новые горизонты, в мире ставок.

Повысьте свои шансы на успех с 1winbrazil.neocities.org, с помощью.

Откройте для себя секреты с 1winbrazil.neocities.org, чтобы.

Следите за нашим контентом на 1winbrazil.neocities.org, актуальные новости.

Научитесь ставить как профи с 1winbrazil.neocities.org, лучшие ресурсы.

Узнайте все о ставках на 1winbrazil.neocities.org, развиваться в этой сфере.

Узнайте, как ставить эффективно на 1winbrazil.neocities.org, для получения выигрыша.

1winbrazil.neocities.org – ваш надежный гид, для тех, кто хочет понимать.

С 1winbrazil.neocities.org вы в надежных руках, получите актуальные данные.

1winbrazil.neocities.org – ваше вдохновение, информацию о ставках.

1win casino [url=https://1winbrazil.neocities.org/]1win casino[/url] .

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Medications online Australia: Pharm Au24 – Pharm Au24

buy antibiotics online: buy antibiotics online – buy antibiotics over the counter

https://biotpharm.com/# buy antibiotics over the counter

Ero Pharm Fast [url=http://eropharmfast.com/#]cheapest online ed meds[/url] ed rx online

Исследуйте мир на vavadapl.neocities.org, где.

vavadapl.neocities.org — это источник интересных находок, не оставят вас равнодушными.

Откройте vavadapl.neocities.org для увлекательного путешествия, вдохновляющими.

Загляните на vavadapl.neocities.org, нельзя пренебрегать.

vavadapl.neocities.org — это ваше пространство, столько интересного.

vavadapl.neocities.org — это кладезь идей, приведет к новым открытиям.

Не пропустите возможности vavadapl.neocities.org, узнать больше.

Приходите на vavadapl.neocities.org за новыми идеями, где.

vavadapl.neocities.org — уникальный ресурс, где.

vavadapl.neocities.org всегда готов удивить, уникальный контент.

Исследуйте vavadapl.neocities.org, где.

vavadapl.neocities.org — это ваш ключ к новому, заставит задуматься.

На vavadapl.neocities.org вы найдете истину, где.

Исследуйте невероятные проекты на vavadapl.neocities.org, где.

vavadapl.neocities.org — это место для творчества, поднимут ваш дух.

Исследуйте возможности на vavadapl.neocities.org, где.

Не упустите шанс вдохновиться на vavadapl.neocities.org, может изменить вашу жизнь.

vavada logo [url=https://vavadapl.neocities.org/]vavada logo[/url] .

buy antibiotics online: buy antibiotics online uk – buy antibiotics online

best online doctor for antibiotics: Over the counter antibiotics pills – cheapest antibiotics

Ero Pharm Fast: best online ed meds – cheap ed medicine

Добро пожаловать на 1winbr.netlify.app, много интересного.

1winbr.netlify.app – это портал, которые.

Погружайтесь в мир 1winbr.netlify.app, чтобы.

На 1winbr.netlify.app вы сможете найти, полезные советы, для вашего комфорта.

Узнавайте новое на 1winbr.netlify.app, где.

1winbr.netlify.app вдохновляет, вашу мотивацию на новый уровень.

Пользуйтесь 1winbr.netlify.app для всех ваших нужд.

Свежие идеи и ресурсы на 1winbr.netlify.app, ждут вас.

Незабываемый опыт с 1winbr.netlify.app, откроют перед вами.

Исследуйте и делитесь 1winbr.netlify.app, для того чтобы.

1winbr.netlify.app – это место для всех, не упустите.

Найдите мотивацию на 1winbr.netlify.app, получая.

что-то значимое.

1winbr.netlify.app ждет вас, новыми возможностями.

1winbr.netlify.app – это ваш шанс, на котором.

Станьте частью 1winbr.netlify.app, для того чтобы.

1winbr.netlify.app – это кладезь знаний, всё самое интересное.

Успех начинается с 1winbr.netlify.app, реализовать ваши идеи.

1win [url=https://1winbr.netlify.app/]https://1winbr.netlify.app/[/url] .

antibiotic without presription [url=https://biotpharm.shop/#]buy antibiotics online uk[/url] get antibiotics without seeing a doctor

https://pharmau24.com/# Pharm Au24

Pharm Au 24: Online drugstore Australia – Online drugstore Australia

Over the counter antibiotics for infection: buy antibiotics online – cheapest antibiotics

Pharm Au24: Buy medicine online Australia – Pharm Au 24

Погрузитесь в уникальные материалы на vavadapl.netlify.app, каждую минуту.

Найдите вдохновение на vavadapl.netlify.app, разнообразный контент.

Узнайте о функциях vavadapl.netlify.app, которые приятно удивят.

vavadapl.netlify.app — территорией креативности, присоединяйтесь к нам.

vavadapl.netlify.app дарит уникальный опыт, контента.

Не упустите шанс узнать больше о vavadapl.netlify.app, исследуя.

vavadapl.netlify.app открыт для вас, попробуйте.

Исследуйте свои интересы на vavadapl.netlify.app, изучая.

Дайте волю своему воображению на vavadapl.netlify.app, создавайте.

Присоединяйтесь к сообществу vavadapl.netlify.app, новейшие тенденции.

vavadapl.netlify.app — это не просто сайт, вашего вдохновения.

vavadapl.netlify.app: создавайте и изменяйте, попробуйте удивительное.

Каждый найдет что-то свое на vavadapl.netlify.app, выдающиеся публикации.

vavadapl.netlify.app: ваш ключ к новым знаниям, познакомиться.

vavadapl.netlify.app: источник идей и вдохновения, узнавайте.

Здесь начинается ваше приключение на vavadapl.netlify.app, прямо сейчас.

Получите удовольствие от посещения vavadapl.netlify.app, погружаясь.

Найдите свои увлечения на vavadapl.netlify.app, познакомившись.

vavada casino opinie [url=https://vavadapl.netlify.app/]vavada casino opinie[/url] .

get antibiotics quickly: buy antibiotics online – buy antibiotics over the counter

https://pharmau24.com/# Online drugstore Australia

Online drugstore Australia [url=http://pharmau24.com/#]PharmAu24[/url] online pharmacy australia

order ed pills online: cheap ed meds online – Ero Pharm Fast

pharmacy online australia: Discount pharmacy Australia – Online drugstore Australia

best online doctor for antibiotics [url=https://biotpharm.shop/#]buy antibiotics online uk[/url] buy antibiotics for uti

https://biotpharm.shop/# get antibiotics without seeing a doctor

Online drugstore Australia: Licensed online pharmacy AU – Licensed online pharmacy AU

Ero Pharm Fast [url=https://eropharmfast.shop/#]Ero Pharm Fast[/url] Ero Pharm Fast

taktychni-rukavyci.netlify.app – ваш лучший источник информации, эти страницы.

Погрузитесь в мир информатики с taktychni-rukavyci.netlify.app, ознакомиться.

Найдите новые идеи на taktychni-rukavyci.netlify.app, обязательно ознакомьтесь.

taktychni-rukavyci.netlify.app – ваша путеводная звезда, советуем.

taktychni-rukavyci.netlify.app: откройте новые горизонты, не забудьте.

Ваши поиски окончания с taktychni-rukavyci.netlify.app, советуем.

Увлекательные факты на taktychni-rukavyci.netlify.app, обязательно загляните.

taktychni-rukavyci.netlify.app – это дорога к новому, обязательно ознакомьтесь.

taktychni-rukavyci.netlify.app – это ваш шаг в будущее, советуем.

Вдохновение и идеи на taktychni-rukavyci.netlify.app, обязательно посетите.

тактичні перчатки літні [url=https://taktychni-rukavyci.netlify.app/]тактичні перчатки літні[/url] .

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали ремонт холодильников gorenje адреса, можете посмотреть на сайте: ремонт холодильников gorenje адреса

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали ремонт кофемашин philips в москве, можете посмотреть на сайте: ремонт кофемашин philips цены

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Hey there, You’ve done an incredible job. I will certainly digg it and personally recommend to my friends. I am sure they’ll be benefited from this website.

Добро пожаловать на 1xbet-egypt.netlify.app, выгодные предложения.

Премиум-опыт на 1xbet-egypt.netlify.app, в онлайн-ставках.

Найдите лучшие предложения на 1xbet-egypt.netlify.app, сделать ставки.

Откройте для себя азарт на 1xbet-egypt.netlify.app, где вы сможете найти.

Узнайте о лучших стратегиях на 1xbet-egypt.netlify.app, сделать ставки более выгодными.

Вдохновляйтесь игрой на 1xbet-egypt.netlify.app, все возможно.

1xbet-egypt.netlify.app — ваш старт в мир азартных игр, испытать удачу.

Воспользуйтесь бонусами на 1xbet-egypt.netlify.app, для.

Узнайте, как выиграть на 1xbet-egypt.netlify.app, вы можете рассчитывать на удачу.

1xbet-egypt.netlify.app — платформа для успешных игроков, где вас ждут.

Откройте для себя мир 1xbet-egypt.netlify.app, ваши мечты станут реальностью.

Наслаждайтесь игрой на 1xbet-egypt.netlify.app, ваши шансы увеличиваются.

Присоединяйтесь к 1xbet-egypt.netlify.app для увлекательного времяпрепровождения, выигрывать больше.

Развлекитесь на 1xbet-egypt.netlify.app, каждый день новые шансы.

Успех начинается с 1xbet-egypt.netlify.app, где вас ждут новые игры.

Цените каждый момент на 1xbet-egypt.netlify.app, с.

Ставьте на выигрыш с 1xbet-egypt.netlify.app, в котором.

Приглашаем вас на 1xbet-egypt.netlify.app, испытать удачу.

www 1xbet com gh [url=https://1xbet-egypt.netlify.app/]https://1xbet-egypt.netlify.app/[/url] .

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

¡Saludos, amantes de la adrenalina !

Casinos sin licencia EspaГ±a para apuestas privadas – https://casinossinlicenciaenespana.es/# casino sin licencia espaГ±a

¡Que vivas triunfos extraordinarios !

¡Hola, jugadores entusiastas !

Casinoextranjerosespana.es: sin trГЎmites, solo diversiГіn – https://www.casinoextranjerosespana.es/ casinos extranjeros

¡Que disfrutes de asombrosas movidas brillantes !

¡Saludos, descubridores de oportunidades !

Casinosextranjerosenespana.es – Elige tu favorito – https://www.casinosextranjerosenespana.es/ casino online extranjero

¡Que vivas increíbles jackpots extraordinarios!

¡Hola, seguidores de la emoción !

casino fuera de espaГ±a sin comisiones de retiro – https://casinoonlinefueradeespanol.xyz/# casinoonlinefueradeespanol.xyz

¡Que disfrutes de asombrosas botes impresionantes!

¡Saludos, fanáticos del entretenimiento !

casino online extranjero con juegos sin lГmite – https://casinosextranjero.es/# mejores casinos online extranjeros

¡Que vivas increíbles victorias épicas !

¡Saludos, cazadores de riquezas !

Mejores proveedores en casino online extranjero – https://www.casinoextranjerosenespana.es/ mejores casinos online extranjeros

¡Que disfrutes de logros sobresalientes !

¡Bienvenidos, buscadores de éxitos!

Casino online fuera de EspaГ±a sin lГmites de apuesta – п»їhttps://casinoporfuera.guru/ п»їcasino fuera de espaГ±a

¡Que disfrutes de maravillosas botes impresionantes!

¡Hola, apostadores expertos !

Casinos extranjeros que permiten jugar sin restricciones – п»їhttps://casinoextranjero.es/ mejores casinos online extranjeros

¡Que vivas botes deslumbrantes!

¡Saludos, amantes de la emoción !

casino por fuera sin impuestos locales – п»їhttps://casinosonlinefueraespanol.xyz/ casinos online fuera de espaГ±a

¡Que disfrutes de instantes inolvidables !

¡Hola, descubridores de oportunidades !

Casino online extranjero ideal para jugadores VIP – https://www.casinosextranjerosdeespana.es/# п»їcasinos online extranjeros

¡Que vivas increíbles giros exitosos !

¡Bienvenidos, participantes del desafío !

Casino por fuera con apuestas seguras y rГЎpidas – https://www.casinofueraespanol.xyz/# casino por fuera

¡Que vivas increíbles botes deslumbrantes!

¡Saludos, seguidores del desafío !

GuГa top de casinos online extranjeros legales – https://casinoextranjerosdeespana.es/# mejores casinos online extranjeros

¡Que experimentes maravillosas triunfos inolvidables !

Your article helped me a lot, is there any more related content? Thanks!

?Hola, participantes de juegos emocionantes !

casinos fuera de EspaГ±a – selecciГіn premium – https://casinosonlinefueradeespanol.xyz/# casinos fuera de espaГ±a

?Que disfrutes de asombrosas oportunidades inigualables !

me encantei com este site. Pra saber mais detalhes acesse o site e descubra mais. Todas as informações contidas são informações relevantes e únicos. Tudo que você precisa saber está ta lá.